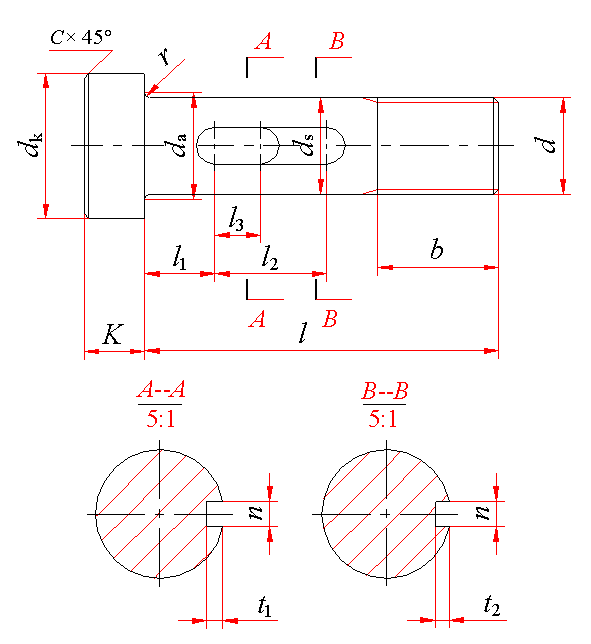

钢网架螺栓球节点用高强度螺栓(GB/T 16939—2016)

钢网架螺栓球节点用高强度螺栓(GB/T 16939—2016)

|

钢网架螺栓球节点用高强度螺栓(GB/T 16939—2016) mm |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||

|

末端按GB2规定 |

||||||||||||||

|

标记示例: 螺纹规格d=30mm、公称长度l=98mm、性能等级为10.9S、表面氧化的钢网架螺栓球节点用高强度螺栓的标记: 螺栓 GB/T 16939 M30×98 |

||||||||||||||

|

螺纹规格 d |

P |

b |

C≈ |

dK |

dS |

K |

r min |

da max |

||||||

|

min |

max |

max |

min |

max |

min |

公称 |

max |

min |

||||||

|

M12 |

1.75 |

15 |

18.5 |

1.5 |

18 |

17.38 |

12.35 |

11.65 |

6.4 |

7.15 |

5.65 |

0.8 |

15.20 |

|

|

M14 |

2 |

17 |

21 |

21 |

20.38 |

14.35 |

13.65 |

7.5 |

8.25 |

6.75 |

17.29 |

|||

|

M16 |

2 |

20 |

24 |

24 |

23.38 |

16.35 |

15.65 |

10 |

10.75 |

9.25 |

19.20 |

|||

|

M20 |

2.5 |

25 |

30 |

30 |

29.38 |

20.42 |

19.58 |

12.5 |

13.4 |

11.6 |

1.0 |

24.40 |

||

|

M24 |

3 |

30 |

36 |

2.0 |

36 |

35.38 |

24.42 |

23.58 |

15 |

15.9 |

14.1 |

28.40 |

||

|

M27 |

3 |

33 |

39 |

41 |

40.38 |

27.42 |

26.58 |

17 |

17.9 |

16.1 |

1.5 |

32.40 |

||

|

M30 |

3.5 |

37 |

44 |

2.5 |

46 |

45.38 |

30.42 |

29.58 |

18.7 |

19.75 |

17.65 |

35.40 |

||

|

M36 |

4 |

44 |

52 |

55 |

54.26 |

36.50 |

35.50 |

22.5 |

23.55 |

21.45 |

42.40 |

|||

|

M39 |

4 |

47 |

55 |

3.0 |

60 |

59.26 |

39.50 |

38.50 |

25 |

26.05 |

23.95 |

2.0 |

45.40 |

|

|

M42 |

4.5 |

50 |

59 |

65 |

64.26 |

42.50 |

41.50 |

26 |

27.05 |

24.95 |

48.60 |

|||

|

M45 |

4.5 |

55 |

64 |

70 |

69.26 |

45.50 |

44.50 |

28 |

29.05 |

26.95 |

52.60 |

|||

|

M48 |

5 |

58 |

68 |

75 |

74.26 |

48.50 |

47.50 |

30 |

31.05 |

28.95 |

56.60 |

|||

|

M56×4 |

4 |

66 |

74 |

90 |

89.13 |

56.60 |

55.40 |

35 |

36.25 |

33.75 |

2.5 |

67.00 |

||

|

M60×4 |

4 |

70 |

78 |

3.5 |

95 |

94.13 |

60.60 |

59.40 |

38 |

39.25 |

36.75 |

71.00 |

||

|

M64×4 |

4 |

74 |

82 |

100 |

99.13 |

64.60 |

63.40 |

40 |

41.25 |

38.75 |

75.00 |

|||

|

M68×4 |

4 |

78 |

86 |

100 |

99.13 |

68.68 |

67.94 |

45 |

46.39 |

43.56 |

79.00 |

|||

|

M72×4 |

4 |

83 |

91 |

105 |

104.13 |

72.72 |

71.98 |

45 |

46.39 |

43.56 |

3.0 |

83.00 |

||

|

M76×4 |

4 |

87 |

95 |

110 |

109.13 |

76.76 |

76.02 |

50 |

51.55 |

48.4 |

87.00 |

|||

|

M80×4 |

4 |

92 |

100 |

4.0 |

125 |

124 |

80.80 |

80.06 |

55 |

56.71 |

53.24 |

91.00 |

||

|

M85×4 |

4 |

98 |

106 |

125 |

124 |

85.85 |

84.98 |

55 |

56.71 |

53.24 |

96.00 |

|||

|

螺纹规格 d |

l |

l1 |

l2 参考 |

l3 |

n |

t1 |

t2 |

|||||||

|

公称 |

max |

min |

公称 |

max |

min |

max |

min |

max |

min |

max |

min |

|||

|

M12 |

50 |

50.80 |

49.20 |

18 |

18.35 |

17.65 |

10 |

4 |

3.3 |

3 |

2.8 |

2.2 |

2.3 |

1.7 |

|

M14 |

54 |

54.95 |

53.05 |

|||||||||||

|

M16 |

62 |

62.95 |

61.05 |

22 |

22.42 |

21.58 |

13 |

|||||||

|

M20 |

73 |

73.95 |

72.05 |

24 |

24.42 |

23.58 |

16 |

5.3 |

5 |

3.30 |

2.70 |

2.80 |

2.20 |

|

|

M24 |

82 |

83.1 |

80.9 |

18 |

||||||||||

|

M27 |

90 |

91.1 |

88.9 |

28 |

28.42 |

27.58 |

20 |

6.3 |

6 |

4.38 |

3.62 |

3.30 |

2.70 |

|

|

M30 |

98 |

99.1 |

96.9 |

24 |

||||||||||

|

M36 |

125 |

126.25 |

123.75 |

43 |

43.50 |

42.50 |

26 |

8.36 |

8 |

5.38 |

4.62 |

4.38 |

3.62 |

|

|

M39 |

128 |

129.25 |

126.75 |

|||||||||||

|

M42 |

136 |

137.25 |

134.75 |

30 |

||||||||||

|

M45 |

145 |

146.25 |

143.75 |

48 |

48.50 |

47.50 |

||||||||

|

M48 |

148 |

149.25 |

146.75 |

|||||||||||

|

M56×4 |

172 |

173.25 |

170.75 |

53 |

53.60 |

52.40 |

42 |

|||||||

|

M60×4 |

196 |

197.45 |

194.55 |

57 |

||||||||||

|

M64×4 |

205 |

206.45 |

203.55 |

58 |

58.60 |

57.40 |

||||||||

|

M68×4 |

215 |

217.3 |

212.3 |

65 |

4 |

8.36 |

8 |

5.38 |

4.62 |

4.38 |

3.62 |

|||

|

M72×4 |

230 |

232.3 |

227.7 |

63 |

63.60 |

62.40 |

70 |

|||||||

|

M76×4 |

240 |

242.3 |

237.7 |

75 |

||||||||||

|

M80×4 |

245 |

247.3 |

242.7 |

80 |

||||||||||

|

M85×4 |

265 |

267.6 |

262.4 |

68 |

68.60 |

67.40 |

85 |

|||||||

|

技术条件 |

材料 |

螺纹公差 |

公差产品等级 |

机械性能等级 |

表面处理 |

表面 缺陷 |

||||||||

|

M12~M24 |

20MnTiB、40Cr、35CrMo |

6g |

除表中规定处,其余按B级 |

M12~M36:10.9S; M39~M85×4:9.8S |

氧化 |

GB/T 5779.1 |

||||||||

|

M27~M36 |

35VB、40Cr、35CrMo |

|||||||||||||

|

M39~M64×4 |

35CrMo、40Cr |

|||||||||||||

|

注:性能等级中的“S”表示钢结构用螺栓。 |

||||||||||||||

|

质量 kg |

|||||||

|

螺纹规格 |

M12 |

M14 |

M16 |

M20 |

M24 |

M27 |

M30 |

|

每1000件钢制品的质量 ≈ |

51.39 |

77.82 |

122.8 |

229.6 |

381.0 |

542.2 |

736.4 |

|

螺纹规格 |

M36 |

M39 |

M42 |

M45 |

M52 |

M56×4 |

M60×4 |

|

每1000件钢制品的质量 ≈ |

1330 |

1655 |

2034 |

2515 |

3799 |

4863 |

6217 |