自润滑镶嵌轴承

自润滑镶嵌轴承

|

特点 |

|---|

|

自润滑轴承是在金属基体上均匀地镶入固体润滑剂,可实现不需加油的自润滑,但初次使用需抹上润滑脂。自润滑轴承特别适用于:为避免污染而不能加油或处于封闭性结构内而不易加油的场合;往复、摇摆运动,频繁启动、制动,重载低速运转,微量滑动以及处于水中或腐蚀性液体中难以形成润滑油膜的场合;作业环境恶劣,注油润滑效果难以发挥的场合。具有耐高温、承重载、抗冲击、防腐蚀的特点。 |

ZRH镶嵌轴承主要性能参数

|

ZRH镶嵌轴承主要性能参数 |

||||||

|---|---|---|---|---|---|---|

|

种 类 |

ZRHQ (基体ZCuSn5Pb5Zn5) |

ZRHH (基体ZCuZn25Al6Fe3Mn3) |

ZRHT (基体HT200) |

|||

|

不加油 |

定期供脂 |

不加油 |

定期供脂 |

不加油 |

定期供脂 |

|

|

允许极限载荷/MPa |

15 |

15 |

25 |

25 |

5 |

8 |

|

允许速度/m·min-1 |

25 |

150 |

15 |

50 |

15 |

96 |

|

允许pv值/MPa·m·min-1 |

60 |

100 |

100 |

150 |

40 |

80 |

|

工作温度/℃ |

400 |

250 |

300 |

|||

|

摩擦因数μ |

0.08~0.25 |

0.08~0.20 |

0.08~0.25 |

0.08~0.20 |

0.08~0.25 |

0.06~0.20 |

|

适用范围 |

中载低速 |

通用 |

低载、价廉 |

|||

|

注:1.订货时说明基体种类。结构型式分WQZ、WQZD、WQPA型和WQPB型。 2.生产厂为武汉油缸厂自润滑分厂。 |

||||||

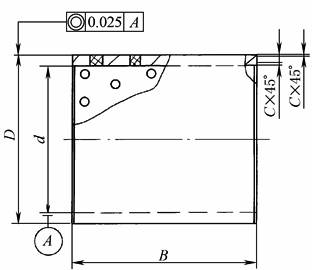

WQZ整体式镶嵌轴承尺寸

|

WQZ整体式镶嵌轴承尺寸 /mm |

||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

标记示例:整体式镶嵌轴承WQZ030 |

代 号 |

d (H7或H8) |

D |

B (h12) |

C |

重量 /kg |

||||||||||||||||||||||||

|

WQZ 030 |

30 |

38 |

s6 |

50 |

1 |

0.190 |

||||||||||||||||||||||||

|

WQZ 035 |

35 |

45 |

55 |

1 |

0.308 |

|||||||||||||||||||||||||

|

WQZ 040 |

40 |

50 |

60 |

1 |

0.378 |

|||||||||||||||||||||||||

|

WQZ 045 |

45 |

55 |

70 |

1 |

0.490 |

|||||||||||||||||||||||||

|

WQZ 050 |

50 |

60 |

75 |

1 |

0.578 |

|||||||||||||||||||||||||

|

WQZ 060 |

60 |

70 |

80 |

2 |

0.728 |

|||||||||||||||||||||||||

|

WQZ 070 |

70 |

85 |

100 |

2 |

1.628 |

|||||||||||||||||||||||||

|

WQZ 080 |

80 |

95 |

100 |

2 |

1.838 |

|||||||||||||||||||||||||

|

WQZ 090 |

90 |

105 |

120 |

2 |

2.457 |

|||||||||||||||||||||||||

|

WQZ 100 |

100 |

115 |

120 |

2 |

2.709 |

|||||||||||||||||||||||||

|

WQZ 110 |

110 |

125 |

r6 |

140 |

2 |

3.455 |

||||||||||||||||||||||||

|

WQZ 120 |

120 |

135 |

150 |

2 |

4.016 |

|||||||||||||||||||||||||

|

WQZ 140 |

140 |

160 |

170 |

2 |

7.140 |

|||||||||||||||||||||||||

|

注:1.轴承座采用整体有衬正滑动轴承座(JB/T 2560—2007)。 2.与外径D相配的座孔偏差为H7。 3.轴承孔与轴颈间的间隙参考值(包括WQZD、WQP)如下。 mm

|

||||||||||||||||||||||||||||||

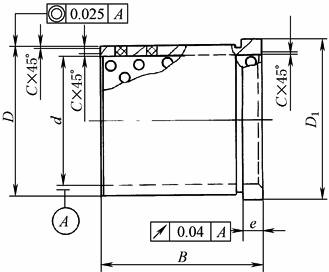

WQZD带挡边整体式镶嵌轴承尺寸

|

WQZD带挡边整体式镶嵌轴承尺寸 /mm |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

标记示例:带挡边整体式镶嵌轴承WQZD030 |

代 号 |

d (H7或H8) |

D |

D1 (d11) |

B (h12) |

e |

C |

重量 /kg |

|

|

WQZD 030 |

30 |

38 |

s6 |

48 |

34 |

6 |

1 |

0.1656 |

|

|

WQZD 035 |

35 |

45 |

55 |

45 |

6.5 |

1 |

0.2975 |

||

|

WQZD 040 |

40 |

50 |

60 |

50 |

7.5 |

1 |

0.3728 |

||

|

WQZD 045 |

45 |

55 |

65 |

55 |

7.5 |

1 |

0.4480 |

||

|

WQZD 050 |

50 |

60 |

70 |

60 |

7.5 |

1 |

0.5302 |

||

|

WQZD 060 |

60 |

70 |

80 |

70 |

10 |

2 |

0.7420 |

||

|

WQZD 070 |

70 |

85 |

95 |

80 |

10 |

2 |

1.428 |

||

|

WQZD 080 |

80 |

95 |

110 |

95 |

12.5 |

2 |

2.015 |

||

|

WQZD 090 |

90 |

105 |

120 |

105 |

12.5 |

2 |

2.445 |

||

|

WQZD 100 |

100 |

115 |

130 |

115 |

12.5 |

2 |

2.918 |

||

|

WQZD 110 |

110 |

125 |

r6 |

140 |

125 |

12.5 |

2 |

3.432 |

|

|

WQZD 120 |

120 |

135 |

150 |

140 |

15 |

2 |

4.197 |

||

|

WQZD 140 |

140 |

160 |

175 |

160 |

20 |

2 |

7.424 |

||

|

WQZD 160 |

160 |

180 |

200 |

180 |

20 |

2 |

9.632 |

||

|

注:1.轴承采用整体有衬正滑动轴承座 (JB/T 2560—2007)。 2.与外径相配座孔的偏差为H7。 |

|||||||||

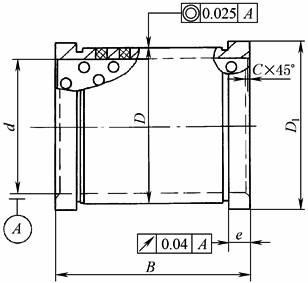

WQP剖分式镶嵌轴承A型尺寸

|

WQP剖分式镶嵌轴承A型尺寸 /mm |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

标记示例:剖分式镶嵌轴承WQP030 A型 |

代 号 |

d (H7或H8) |

D |

D1 (d11) |

B (h12) |

e |

C |

重量 /kg |

|

|

WQP 030 |

30 |

38 |

s6 |

48 |

34 |

6 |

1 |

0.201 |

|

|

WQP 035 |

35 |

45 |

55 |

45 |

6.5 |

1 |

0.343 |

||

|

WQP 040 |

40 |

50 |

60 |

50 |

7.5 |

1 |

0.406 |

||

|

WQP 045 |

45 |

55 |

65 |

55 |

7.5 |

1 |

0.511 |

||

|

WQP 050 |

50 |

60 |

70 |

60 |

7.5 |

1 |

0.598 |

||

|

WQP 060 |

60 |

70 |

80 |

70 |

10 |

2 |

0.847 |

||

|

WQP 070 |

70 |

85 |

95 |

80 |

10 |

2 |

1.554 |

||

|

WQP 080 |

80 |

95 |

110 |

95 |

12.5 |

2 |

2.284 |

||

|

WQP 090 |

90 |

105 |

120 |

105 |

12.5 |

2 |

2.741 |

||

|

WQP 100 |

100 |

115 |

130 |

115 |

12.5 |

2 |

3.239 |

||

|

WQP 110 |

110 |

125 |

r6 |

140 |

125 |

12.5 |

2 |

3.780 |

|

|

WQP 120 |

120 |

135 |

150 |

140 |

15 |

2 |

4.646 |

||

|

WQP 140 |

140 |

160 |

175 |

160 |

20 |

2 |

8.127 |

||

|

WQP 160 |

160 |

180 |

200 |

180 |

20 |

2 |

10.696 |

||

|

注:1.A型轴承采用对开式二螺柱正滑动轴承座(摘自JB/T2561—1991)。 2.B型采用对开式四螺柱正滑动轴承座(摘自JB/T 2562—1991)或对开式四螺柱斜滑动轴承座(摘自JB/T 2563—1991)。B型尺寸见生产厂样本。 3.与外径相配座孔偏差为H7。 |

|||||||||

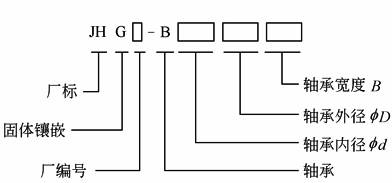

JHG镶嵌轴承性能参数

|

JHG镶嵌轴承性能参数 |

||||||||

|---|---|---|---|---|---|---|---|---|

|

型 号 |

基体材料 |

极限动 载荷 /MPa |

最高滑动 速度 /m·s-1 自润滑 |

极限pυ值 /MPa·m· s-1 自润滑 |

适用温度 范围/℃ |

硬度 HB |

摩擦因数 μ |

适 用 范 围 |

|

JHG1 |

铝黄铜 |

95 |

0.4 |

1.4 |

<300 |

>200 |

0.06~0.2 |

适用于高载荷、低速、耐腐蚀、耐磨损的部位,如桥梁支承板、橡胶模具、塑料模具中的耐磨滑板、滑块、导向套管、轴承等 |

|

JHG2 |

铝青铜 |

50 |

0.2 |

1.0 |

<300 |

>160 |

适用于较高载荷、低速,在大气、淡水、海水中均有优良的耐腐蚀性。如船舶、码头机械、海洋机械等需耐腐蚀的滑板、轴承等 |

|

|

JHG3 |

锡青铜 ZCuSn5Zn5Pb5 |

40 |

0.4 |

0.6 |

<280 |

>60 |

适用于较高载荷、中等滑动速度下工作的耐磨、耐腐蚀零件,如轴承、滑板、滑块等 |

|

|

JHG4 |

铸铁 |

60 |

0.5 |

0.8 |

<400 |

>180 |

具有较好的耐热性和良好的减振性,适用于高的载荷,如支承板、耐磨滑板、滑块、轴承等 |

|

|

HT250 |

||||||||

|

JHG5 |

不锈钢 SUS304 |

70 |

0.2 |

0.6 |

<400 |

>150 |

具有良好的耐腐蚀性能,主要用于耐腐蚀要求较高的部位,如食品加工、化学和印染工业以及一般机械制造中滑板、滑块、轴承等 |

|

|

JHG6 |

结构钢 S45C |

95 |

0.2 |

1.0 |

<350 |

>40HRC |

适用于高的载荷,有较高强度、塑性和韧性。常用于耐磨滑板、滑块、轴承等 |

|

|

JHG7 |

轴承钢 GCr15 |

240 |

0.1 |

1.0 |

<350 |

>60HRC |

适用于高载荷、高强度的重型机械中支承轴承、耐磨滑板、滑块等 |

|

|

注:1.订货时说明基体材料。 2.初次使用应抹润滑脂,由产品厂方提供自制润滑脂。 3.生产厂为北京市朝阳建华无油润滑轴承厂。 |

||||||||

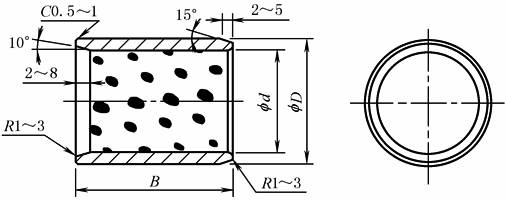

JHG镶嵌轴承尺寸

|

JHG镶嵌轴承尺寸 mm |

|||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||||||||||||||||

|

轴承 |

推荐轴颈及轴承座孔 |

|

|||||||||||||||||||||

|

内径 d(F7) |

外径 D |

轴颈 直径 |

座孔 直径(H7) |

10 JHG |

12 JHG |

15 JHG |

16 JHG |

20 JHG |

25 JHG |

30 JHG |

35 JHG |

40 JHG |

50 JHG |

60 JHG |

70 JHG |

80 JHG |

100 JHG |

120 JHG |

130 JHG |

140 JHG |

150 JHG |

||

|

12 |

+0.034 +0.016 |

18 |

12 |

18 |

+0.018 0 |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

19 |

13 |

19 |

+0.021 0 |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

20 |

14 |

20 |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

15 |

21 |

15 |

21 |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

16 |

22 |

16 |

22 |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

||

|

18 |

24 |

18 |

24 |

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

||

|

20 |

+0.041 +0.020 |

28 |

20 |

28 |

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

20 |

30 |

20 |

30 |

|

|

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

||

|

25 |

33 |

25 |

33 |

+0.025 0 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

|

25 |

35 |

25 |

35 |

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

||

|

30 |

38 |

30 |

38 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

||

|

30 |

40 |

30 |

40 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

||

|

35 |

+0.050 +0.025 |

44 |

35 |

44 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

35 |

45 |

35 |

45 |

|

|

|

|

|

● |

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

||

|

40 |

50 |

40 |

50 |

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

||

|

40 |

55 |

40 |

55 |

+0.030 0 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

45 |

56 |

45 |

56 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

||

|

45 |

60 |

45 |

60 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

||

|

50 |

60 |

50 |

60 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

||

|

50 |

62 |

50 |

62 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

||

|

50 |

65 |

50 |

65 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

||

|

55 |

+0.060 +0.030 |

70 |

55 |

70 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

|

|

|

|

|

|

|

|

60 |

74 |

60 |

74 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

|

||

|

60 |

75 |

60 |

75 |

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

||

|

63 |

75 |

63 |

75 |

|

|

|

|

|

|

|

|

|

● |

● |

● |

● |

|

|

|

|

|

||

|

65 |

80 |

65 |

80 |

|

|

|

|

|

|

|

|

|

● |

● |

● |

|

|

|

|

|

|

||

|

65 |

85 |

65 |

85 |

+0.035 0 |

|

|

|

|

|

|

|

|

|

● |

● |

● |

● |

|

|

|

|

|

|

|

70 |

85 |

70 |

85 |

|

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

|

||

|

70 |

90 |

70 |

90 |

|

|

|

|

|

|

|

|

|

● |

● |

● |

● |

|

|

|

|

|

||

|

75 |

90 |

75 |

95 |

|

|

|

|

|

|

|

|

|

|

● |

● |

● |

|

|

|

|

|

||

|

75 |

95 |

75 |

95 |

|

|

|

|

|

|

|

|

|

|

● |

● |

● |

|

|

|

|

|

||

|

80 |

96 |

80 |

96 |

|

|

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

||

|

80 |

100 |

80 |

100 |

|

|

|

|

|

|

|

|

● |

● |

● |

● |

● |

● |

● |

|

|

|

||

|

90 |

+0.071 +0.036 |

110 |

90 |

110 |

|

|

|

|

|

|

|

|

|

|

● |

|

● |

● |

● |

|

|

|

|

|

100 |

120 |

100 |

120 |

|

|

|

|

|

|

|

|

|

|

● |

● |

● |

● |

● |

|

● |

|

||

|

110 |

130 |

110 |

130 |

+0.040 0 |

|

|

|

|

|

|

|

|

|

|

|

|

● |

● |

● |

|

|

|

|

|

120 |

140 |

120 |

140 |

|

|

|

|

|

|

|

|

|

|

|

|

● |

● |

● |

|

● |

|

||

|

125 |

+0.083 +0.043 |

145 |

125 |

145 |

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

● |

|

|

|

|

|

130 |

150 |

130 |

150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

● |

|

|

||

|

140 |

160 |

140 |

160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

|

|

|

||

|

150 |

170 |

150 |

170 |

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

|

● |

|

||

|

160 |

180 |

160 |

180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

|

● |

● |

||

|

注:1.轴颈、轴承外径的推荐公差为,对于重载荷,轴颈d8,外径p7;对于轻载荷,轴颈e7,外径m6;对于精密配合,轴颈f7,外径m6。 2.未列出的规格尺寸,可按用户要求定制。 3.JHG固体镶嵌除轴套制品外,还可制成减磨止推垫圈、翻边轴套、内外球型轴承、滑板、导轨板等。可与生产厂家联系。 |

|||||||||||||||||||||||