自润滑复合材料卷制轴套

概述

|

概述 |

|---|

|

自润滑复合材料轴套是由塑料、青铜、钢背通过烧结、塑化、辊轧(塑料能压入多孔青铜球粉层内)等工艺卷制而成的。分JH1型和JH2型,二者其中间青铜层均是多孔青铜球粉层,外层均是带镀层的钢背。二者的主要区别是内层,JH1内层是聚四氟乙烯(PTFE)+铅(Pb)及其他充填物,适用温度范围大,使用较广;JH2内层是改性聚甲醛(POM),表面轧出一定规律的储油坑,适用温度范围小一些,是较好的边界润滑材料,多用于停止、启动频繁的场合,安装时需在储油坑中填满润滑脂。二者主要性能及应用见表自润滑复合材料卷制轴套的性能及应用。卷制轴套的标准有GB/T 12613.1—2011(尺寸)、GB/T 12613.2—2011(外径和内径的检测数据)、GB/T 12613.3—2011(润滑油孔、润滑油槽和润滑油穴)和GB/T 12613.4—2011(材料)。 |

自润滑复合材料卷制轴套的性能及应用

|

自润滑复合材料卷制轴套的性能及应用 |

|||||||

|---|---|---|---|---|---|---|---|

|

主要 性能 |

|

轴承承载能力 /MPa |

适用温度范围 /℃ |

线胀系数 /℃-1 |

热导率 /W·(m·K)-1 |

摩擦因数 μ |

极限pv值 /MPa·m·s-1 |

|

JH1 |

连续运转12 一般运转60 低速运转140 |

-200~280 |

≤30×10-6 |

≥2.35 |

有油<0.06 无油<0.20 |

有油<50 无油<3.6 |

|

|

JH2 |

连续运转50 低速运转140 |

连续-40~9 断续-40~130

|

≤70×10-6 |

≥1.7 |

有油<0.06 |

有油<22.0 干<2.8 |

|

|

应

用

特

点 |

JH1型及 其派 生型 |

(1)静、动摩擦因数接近,防爬、减爬(即防粘滑运动)性能优良。适用于机构中微量进给、低速运动和重复定位要求较高的地方 (2)摩擦因数小,并能在无油、少油的工况条件下正常工作,能简化润滑系统,减少维护。安装时抹上润滑脂,使用效果更好 (3)能吸收振动,减少运动中的噪声。不产生聚积静电 (4)化学性能稳定,在对钢背材料进行特殊处理或采用不锈钢后,能在酸、碱、盐水溶液中或SF6气体、电弧分解物的气氛中工作。如印刷,造纸机械、化工设备、海洋机械、高压开关等,在JH1基础上开发的其他型号有: JH1G改进型——有更低的摩擦因数,能承受更大瞬时速度的变化和载荷的变化。适用边界润滑、无油、少油的轴承部位,如汽车减振器等 JH1Z增强型——有更高的承载能力和良好的抗磨损性能,是为高pv值而设计的,如齿轮泵、叶片泵、柱塞泵等 JH1W无铅型——采用不含铅的改性PTFE减摩层,适用于食品、医疗机械和家用电器等 JH1T铜背、JH1B不锈钢背等,具有良好的导热性和耐腐蚀性,可用于冶金、化工、海洋等环境,此外,还可制成翻边轴套、止推垫圈、球型轴承、机床导轨板等 |

|||||

|

JH2型 |

安装时在油坑中充满润滑脂,使用中定期加入润滑脂或稀油,效果更好。具有优良的耐磨性,适用于边界润滑条件,特别适合重载、低速停止、启动频繁不能形成润滑膜的旋转运动、摆动等机械的轴承。轴套可根据使用精度要求,在安装后对减摩层进行精加工。除轴套外,还可制成止推垫圈、机床导轨板等,其派生型为JH2W无铅型、JH2G改进型。JH2含铅型较JH2W有较好的耐磨性 |

||||||

|

轴

套

安

装 |

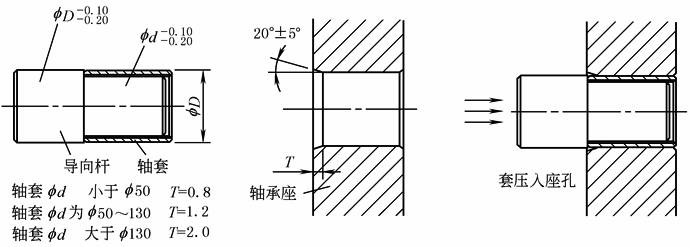

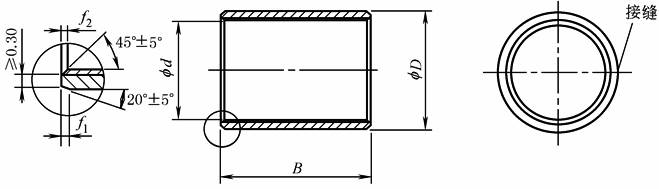

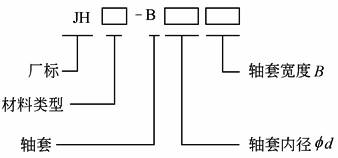

JH1、JH2型自润滑复合材料轴套的安装注意事项: (1)轴套座孔及轴劲尺寸偏差的选择,可按表JH1型轴套尺寸中的推荐值选取。特殊环境可由试验来决定其合理间隙 (2)与轴套内径相配合的轴颈表面粗糙度Ra≤0.8μm,表面硬度≥46HRC (3)轴套座孔的表面粗糙度要小于Ra1.6μm。轴套座孔的压入端面应按T×20°倒角,并去除毛刺,涂少量的润滑脂以利于压入。轴套压入时,应先自制一个导向杆,用专用工具或压力机垂直地压入轴套座孔,应避免直接敲打轴套的端面。对导向杆、座孔的要求见下图 (4)JH1轴套内径工作表面(塑料面)不允许进行车、镗、磨、铰、刮等加工 (5)在安装轴套时,应避免轴套的接缝处在承受最大载荷的方向 (6)同一个座孔安装两个以上轴套时,轴套其接缝应在同一方向上,并对齐,且轴套之间应留有1~2mm的间隙 (7)当需要限制工作轴的轴向移动时,可加装止推垫圈或采用翻边轴套

|

||||||

|

注:生产厂为北京市朝阳建华无油润滑轴承厂。 |

|||||||

JH1型轴套尺寸

|

JH1型轴套尺寸 mm |

||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||

|

轴套 |

推荐轴颈及轴套座孔 |

轴套宽度B±0.25 |

||||||||||||||||||||||||

|

内径Φ d |

外径Φ D |

轴颈 |

座孔 |

6 |

8 |

10 |

12 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

60 |

70 |

80 |

90 |

100 |

f1 |

f2 |

||||

|

尺寸 |

(H9) |

尺寸 |

偏差 |

尺寸 |

(f7) |

尺寸 |

(H7) |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

|

6 |

+0.036 0 |

8 |

+0.055 +0.025 |

6 |

-0.010 -0.022 |

8 |

+0.015 0 |

0606 |

0608 |

0610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6 ±0.4 |

<0.4 |

|

8 |

10 |

8 |

-0.013 -0.028 |

10 |

0806 |

0808 |

0810 |

0812 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

10 |

12 |

+0.065 +0.030 |

10 |

12 |

+0.018 0 |

1006 |

1008 |

1010 |

1012 |

1015 |

1020 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

12 |

+0.043 0 |

14 |

12 |

-0.016 -0.034 |

14 |

1206 |

1208 |

1210 |

1212 |

1215 |

1220 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

14 |

16 |

14 |

16 |

|

|

1410 |

1412 |

1415 |

1420 |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

15 |

17 |

15 |

17 |

|

|

1510 |

1512 |

1515 |

1520 |

1525 |

|

|

|

|

|

|

|

|

|

|

||||||

|

16 |

18 |

16 |

18 |

|

|

1610 |

1612 |

1615 |

1620 |

1625 |

|

|

|

|

|

|

|

|

|

|

||||||

|

18 |

20 |

+0.075 +0.035 |

18 |

20 |

+0.021 0 |

|

|

1810 |

1812 |

1815 |

1820 |

1825 |

|

|

|

|

|

|

|

|

|

|

||||

|

20 |

+0.052 0 |

23 |

20 |

-0.020 -0.041 |

23 |

|

|

2010 |

2012 |

2015 |

2020 |

2025 |

2030 |

|

|

|

|

|

|

|

|

|

0.6 ±0.4 |

0.4 ±0.3 |

||

|

22 |

25 |

22 |

25 |

|

|

2210 |

2212 |

2215 |

2220 |

2225 |

2230 |

|

|

|

|

|

|

|

|

|

||||||

|

24 |

27 |

24 |

27 |

|

|

|

|

2415 |

2420 |

2425 |

2430 |

|

|

|

|

|

|

|

|

|

||||||

|

25 |

28 |

25 |

28 |

|

|

2510 |

2512 |

2515 |

2520 |

2525 |

2530 |

2535 |

|

|

|

|

|

|

|

|

||||||

|

28 |

32 |

+0.085 +0.050 |

28 |

32 |

+0.025 0 |

|

|

|

2812 |

2815 |

2820 |

2825 |

2830 |

|

|

|

|

|

|

|

|

|

1.2 ±0.4 |

0.4 ±0.3 |

||

|

30 |

34 |

30 |

34 |

|

|

|

3012 |

3015 |

3020 |

3025 |

3030 |

|

3040 |

|

|

|

|

|

|

|

||||||

|

32 |

+0.062 0 |

36 |

32 |

-0.025 -0.050 |

36 |

|

|

|

|

|

3220 |

3225 |

3230 |

|

3240 |

|

|

|

|

|

|

|

||||

|

35 |

39 |

35 |

39 |

|

|

|

3512 |

3515 |

3520 |

3525 |

3530 |

|

3540 |

3545 |

3550 |

|

|

|

|

|

||||||

|

38 |

42 |

38 |

42 |

|

|

|

|

|

3820 |

3825 |

3830 |

|

3840 |

|

3850 |

|

|

|

|

|

||||||

|

40 |

44 |

40 |

44 |

|

|

|

4012 |

4015 |

4020 |

4025 |

4030 |

|

4040 |

|

4050 |

|

|

|

|

|

||||||

|

45 |

50 |

45 |

50 |

|

|

|

|

|

4520 |

4525 |

4530 |

|

4540 |

|

4550 |

4560 |

|

|

|

|

1.8 ±0.6 |

0.6 ±0.4 |

||||

|

50 |

55 |

+0.100 +0.055 |

50 |

55 |

+0.030 0 |

|

|

|

|

|

5020 |

5025 |

5030 |

|

5040 |

|

|

5060 |

|

|

|

|

||||

|

55 |

+0.074 0 |

60 |

+0.100 +0.055 |

55 |

-0.030 -0.060 |

60 |

+0.030 0 |

|

|

|

|

|

|

|

5530 |

|

5540 |

|

|

5560 |

5570 |

|

|

|

||

|

60 |

65 |

60 |

65 |

|

|

|

|

|

|

|

6030 |

|

6040 |

|

6050 |

6060 |

6070 |

|

|

|

||||||

|

65 |

70 |

65 |

70 |

|

|

|

|

|

|

|

6530 |

|

6540 |

|

|

6560 |

|

6080 |

|

|

||||||

|

70 |

75 |

70 |

75 |

|

|

|

|

|

|

|

|

|

7040 |

|

|

7060 |

|

7080 |

|

|

||||||

|

75 |

80 |

75 |

80 |

|

|

|

|

|

|

|

7530 |

|

7540 |

|

|

7560 |

|

7580 |

|

|

||||||

|

80 |

85 |

+0.120 +0.070 |

80 |

0 -0.046 |

85 |

+0.035 0 |

|

|

|

|

|

|

|

|

|

8040 |

|

|

8060 |

|

8080 |

|

|

|||

|

85 |

+0.087 0 |

90 |

85 |

0 -0.054 |

90 |

|

|

|

|

|

|

|

|

|

8540 |

|

|

8560 |

|

8580 |

|

|

||||

|

90 |

95 |

90 |

95 |

|

|

|

|

|

|

|

|

|

9040 |

|

|

9060 |

|

|

9090 |

|

||||||

|

95 |

100 |

95 |

100 |

|

|

|

|

|

|

|

|

|

9540 |

|

9550 |

9560 |

|

9580 |

|

95100 |

||||||

|

100 |

105 |

100 |

105 |

|

|

|

|

|

|

|

|

|

|

|

|

10060 |

|

|

|

100100 |

||||||

|

105 |

110 |

105 |

110 |

|

|

|

|

|

|

|

|

|

|

|

|

10560 |

|

|

|

105100 |

||||||

|

110 |

115 |

110 |

115 |

|

|

|

|

|

|

|

|

|

|

|

|

11060 |

|

|

|

110100 |

||||||

|

115 |

120 |

115 |

120 |

|

|

|

|

|

|

|

|

|

|

|

11550 |

11560 |

11570 |

|

|

|

||||||

|

120 |

125 |

+0.170 +0.100 |

120 |

125 |

+0.040 0 |

|

|

|

|

|

|

|

|

|

|

|

12050 |

12060 |

|

|

|

120100 |

||||

|

125 |

+0.100 0 |

130 |

125 |

0 -0.063 |

130 |

|

|

|

|

|

|

|

|

|

|

|

|

12560 |

|

|

|

125100 |

||||

|

130 |

135 |

130 |

135 |

|

|

|

|

|

|

|

|

|

|

|

|

13060 |

|

|

|

130100 |

||||||

|

135 |

140 |

135 |

140 |

|

|

|

|

|

|

|

|

|

|

|

|

13560 |

|

13580 |

|

|

||||||

|

140 |

145 |

+0.225 +0.125 |

140 |

145 |

|

|

|

|

|

|

|

|

|

|

|

|

14060 |

|

14080 |

|

140100 |

|||||

|

150 |

155 |

150 |

155 |

|

|

|

|

|

|

|

|

|

|

|

|

15060 |

|

15080 |

|

150100 |

||||||

|

160 |

165 |

160 |

165 |

|

|

|

|

|

|

|

|

|

|

|

|

16060 |

|

16080 |

|

160100 |

||||||

|

170 |

175 |

170 |

175 |

|

|

|

|

|

|

|

|

|

|

|

|

17060 |

|

17080 |

|

170100 |

||||||

|

180 |

185 |

180 |

185 |

+0.046 0 |

|

|

|

|

|

|

|

|

|

|

|

|

18060 |

|

18080 |

|

180100 |

|||||

|

190 |

+0.115 0 |

195 |

190 |

0 -0.072 |

195 |

|

|

|

|

|

|

|

|

|

|

|

|

19060 |

|

19080 |

|

190100 |

||||

|

200 |

205 |

200 |

205 |

|

|

|

|

|

|

|

|

|

|

|

|

20060 |

|

20080 |

|

|

||||||

|

250 |

+0.130 0 |

255 |

250 |

0 -0.081 |

255 |

+0.052 0 |

|

|

|

|

|

|

|

|

|

|

|

|

25060 |

|

25080 |

|

|

|||

|

255 |

260 |

255 |

260 |

|

|

|

|

|

|

|

|

|

|

|

|

25560 |

|

25580 |

|

|

||||||

|

注:1.表中尺寸系列符合GB/T 12613.1—2011。 2.生产厂也可提供翻边轴套和止推垫圈的系列产品。本表中没有的规格,可按用户要求定制。 |

||||||||||||||||||||||||||

JH2、JH2W、JH2G型轴套尺寸

|

JH2、JH2W、JH2G型轴套尺寸 mm |

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||||||||||||||||||||||

|

轴套 |

推荐轴颈及轴套座孔 |

油孔 |

轴套宽度B±0.25 |

||||||||||||||||||||||||||

|

内径Φ d |

外径Φ D |

轴颈 |

座孔 |

8 |

10 |

12 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

60 |

65 |

70 |

80 |

90 |

95 |

100 |

110 |

f1 |

f2 |

|||||

|

尺寸 |

偏差 |

尺寸 |

偏差 |

尺寸 |

(h8) |

尺寸 |

(H7) |

Φ d1 |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

JH |

|

8 |

+0.083 +0.025 |

10 |

+0.055 +0.026 |

8 |

0 -0.022 |

10 |

+0.015 0 |

4 |

0808 |

0810 |

0812 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6 ± 0.4 |

< 0.4 |

|

10 |

+0.102 +0.032 |

12 |

+0.065 +0.030 |

10 |

12 |

+0.018 0 |

|

1010 |

1012 |

1015 |

1020 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

12 |

14 |

12 |

0 -0.027 |

14 |

|

1210 |

1212 |

1215 |

1220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

14 |

16 |

14 |

16 |

|

|

|

1415 |

1420 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

15 |

17 |

15 |

17 |

|

1510 |

1512 |

1515 |

1520 |

1525 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

16 |

18 |

16 |

18 |

|

|

|

1615 |

1620 |

1625 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

18 |

20 |

+0.075 +0.035 |

18 |

20 |

|

|

|

1815 |

1820 |

1825 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

20 |

+0.124 +0.040 |

23 |

20 |

0 -0.033 |

23 |

+0.021 0 |

|

2010 |

2012 |

2015 |

2020 |

2025 |

2030 |

|

|

|

|

|

|

|

|

|

|

|

|

0.6 ± 0.4 |

0.4 ± 0.3 |

||

|

22 |

25 |

22 |

25 |

6 |

|

|

|

2212 |

2220 |

2225 |

2230 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

24 |

27 |

24 |

27 |

|

|

|

2415 |

2420 |

2425 |

2430 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

25 |

28 |

25 |

28 |

|

|

|

2515 |

2520 |

2525 |

2530 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

28 |

32 |

+0.085 +0.045 |

28 |

32 |

+0.025 0 |

|

|

|

|

2820 |

2825 |

2830 |

|

|

|

|

|

|

|

|

|

|

|

|

1.2 ± 0.4 |

0.4 ± 0.3 |

|||

|

30 |

34 |

30 |

34 |

|

|

|

|

3020 |

|

3030 |

|

3040 |

|

|

|

|

|

|

|

|

|

|

|||||||

|

32 |

+0.150 +0.050 |

36 |

32 |

0 |

36 |

|

|

|

|

3220 |

|

3230 |

3235 |

3240 |

|

|

|

|

|

|

|

|

|

|

|||||

|

35 |

39 |

35 |

-0.039 |

39 |

|

|

|

|

3520 |

|

3530 |

3535 |

3540 |

|

3550 |

|

|

|

|

|

|

|

|

||||||

|

40 |

44 |

40 |

|

44 |

8 |

|

|

|

|

4020 |

|

4030 |

|

4040 |

|

4050 |

|

|

|

|

|

|

|

|

|||||

|

45 |

50 |

45 |

|

50 |

|

|

|

|

4520 |

|

4530 |

|

4540 |

4545 |

4550 |

4560 |

|

|

|

|

|

|

|

1.8 ± 0.6 |

0.6 ± 0.4 |

||||

|

50 |

55 |

+0.100 +0.055 |

50 |

|

55 |

+0.030 0 |

|

|

|

|

|

|

|

|

5040 |

|

5050 |

5060 |

|

|

|

|

|

|

|

||||

|

55 |

+0.180 +0.060 |

60 |

55 |

0 |

60 |

|

|

|

|

5520 |

5525 |

5530 |

|

5540 |

|

5550 |

5560 |

|

|

|

|

|

|

|

|||||

|

60 |

65 |

60 |

-0.046 |

65 |

|

|

|

|

|

|

6030 |

|

6040 |

|

|

6060 |

|

6070 |

|

|

|

|

|

||||||

|

65 |

70 |

65 |

0 |

70 |

|

|

|

|

|

|

|

|

6540 |

|

6550 |

6560 |

|

6570 |

|

|

|

|

|

||||||

|

70 |

75 |

70 |

-0.046 |

75 |

|

|

|

|

|

|

|

|

7040 |

|

7050 |

7060 |

7065 |

7070 |

7080 |

|

|

|

|

||||||

|

75 |

80 |

75 |

|

80 |

9.5 |

|

|

|

|

|

|

|

|

7540 |

|

|

7560 |

|

|

7580 |

|

|

|

|

|||||

|

80 |

85 |

+0.120 +0.070 |

80 |

|

85 |

+0.035 0 |

|

|

|

|

|

|

|

|

8040 |

|

|

8060 |

|

|

8080 |

|

|

80100 |

|

||||

|

|

|

|

|

||||||||||||||||||||||||||

|

85 |

+0.212 +0.072 |

90 |

85 |

0 |

90 |

|

|

|

|

|

|

8530 |

|

8540 |

|

|

8560 |

|

|

8580 |

|

|

85100 |

|

|||||

|

90 |

95 |

90 |

-0.054 |

95 |

|

|

|

|

|

|

|

|

9040 |

|

|

9060 |

|

|

9080 |

9090 |

|

90100 |

|

||||||

|

95 |

100 |

95 |

|

100 |

|

|

|

|

|

|

|

|

|

|

|

9560 |

|

|

9580 |

|

|

95100 |

|

||||||

|

100 |

105 |

100 |

|

105 |

|

|

|

|

|

|

|

|

|

|

10050 |

10060 |

|

|

10080 |

|

10095 |

|

|

||||||

|

105 |

110 |

105 |

|

110 |

|

|

|

|

|

|

|

|

|

|

|

10560 |

|

|

10580 |

|

|

|

105110 |

||||||

|

110 |

115 |

110 |

|

115 |

|

|

|

|

|

|

|

|

|

|

|

11060 |

|

|

11080 |

|

|

|

110110 |

||||||

|

115 |

120 |

115 |

|

120 |

|

|

|

|

|

|

|

|

|

|

11550 |

11560 |

|

11570 |

|

|

|

115100 |

|

||||||

|

120 |

125 |

+0.170 +0.100 |

120 |

|

125 |

+0.040 0 |

|

|

|

|

|

|

|

|

|

|

|

12060 |

|

|

12080 |

|

|

120100 |

120110 |

||||

|

125 |

+0.245 +0.085 |

130 |

125 |

0 -0.063 |

130 |

|

|

|

|

|

|

|

|

|

|

|

12560 |

|

|

12580 |

|

|

125100 |

125110 |

|||||

|

130 |

135 |

130 |

135 |

11 |

|

|

|

|

|

|

|

|

|

|

13050 |

13060 |

|

|

13080 |

|

|

130100 |

|

||||||

|

135 |

140 |

135 |

140 |

|

|

|

|

|

|

|

|

|

|

|

13560 |

|

|

13580 |

|

|

135100 |

|

|||||||

|

140 |

145 |

+0.225 +0.125 |

140 |

145 |

|

|

|

|

|

|

|

|

|

|

14050 |

14060 |

|

|

14080 |

|

|

140100 |

|

||||||

|

150 |

155 |

150 |

155 |

|

|

|

|

|

|

|

|

|

|

15050 |

15060 |

|

|

15080 |

|

|

150100 |

|

|||||||

|

160 |

165 |

160 |

165 |

|

|

|

|

|

|

|

|

|

|

16050 |

16060 |

|

|

16080 |

|

|

160100 |

|

|||||||

|

170 |

175 |

170 |

175 |

|

|

|

|

|

|

|

|

|

|

17050 |

17060 |

|

|

17080 |

|

|

170100 |

|

|||||||

|

180 |

185 |

180 |

185 |

+0.046 0 |

|

|

|

|

|

|

|

|

|

|

18050 |

18060 |

|

|

18080 |

|

|

180100 |

|

||||||

|

190 |

+0.285 +0.100 |

195 |

190 |

0 -0.072 |

195 |

|

|

|

|

|

|

|

|

|

|

19050 |

19060 |

|

|

19080 |

|

|

190100 |

|

|||||

|

200 |

205 |

200 |

205 |

|

|

|

|

|

|

|

|

|

|

20050 |

20060 |

|

|

20080 |

|

|

200100 |

|

|||||||

|

250 |

255 |

250 |

0 -0.081 |

255 |

0.052 0 |

12 |

|

|

|

|

|

|

|

|

|

|

25050 |

25060 |

|

|

25080 |

|

|

250100 |

|

||||

|

255 |

+0.320 +0.110 |

260 |

255 |

260 |

|

|

|

|

|

|

|

|

|

|

25550 |

25560 |

|

|

25580 |

|

|

255100 |

|

||||||

|

注:1.如组装后轴套内径有精加工要求时,应在订货时说明,厂家将留出加工余量。推荐精加工后轴套内径尺寸公差为:H7,轴颈尺寸公差为:d8。表为推荐精加工后尺寸。 2.表中未标出的规格及油孔Φ d1,可按用户要求定制,需在订货时说明。 3.表中尺寸系列符合GB/T12613.1—2011。 |