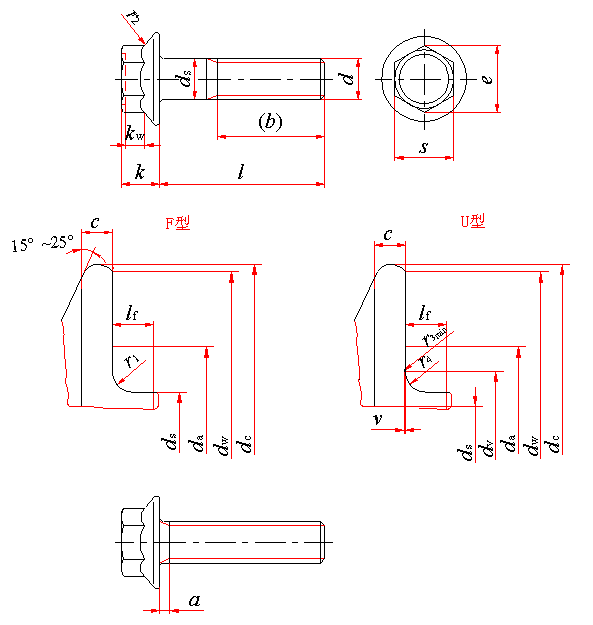

六角法兰面螺栓 细牙 小系列(GB/T 16674.2—2016)

六角法兰面螺栓 细牙 小系列(GB/T 16674.2—2016)

|

六角法兰面螺栓 细牙 小系列(GB/T 16674.2—2016) mm |

||||||||

|---|---|---|---|---|---|---|---|---|

|

|

||||||||

|

标记示例: 螺纹规格d =M12×1.25、细牙螺纹、公称长度l=80mm、由制造者任选F型或U型、性能等级为8.8级、表面氧化、产品等级为A级的小六角系列六角法兰面螺栓的标记: 螺栓 GB/T 16674.2 M12×1.25×80 螺纹规格d =M12×1.25、细牙螺纹、公称长度l=80mm、F型、性能等级为8.8级、表面氧化、产品等级为A级的小六角系列六角法兰面螺栓的标记: 螺栓 GB/T 16674.2 M12×1.25×80-F 如在特殊情况下,要求细杆型式时,则应在标记中增加“R”: 螺栓 GB/T 16674.2 M12×1.25×80-R |

||||||||

|

螺纹规格 |

M8×1 |

M10×1 M10×1.25 |

M12×1.25 M12×1.5 |

(M14×1.5) |

M16×1.5 |

|||

|

a |

max |

3 |

3 |

4.5 |

4.5 |

4.5 |

||

|

min |

1 |

1 |

1.5 |

1.5 |

1.8 |

|||

|

b参考 |

l公称≤125mm |

22 |

26 |

30 |

34 |

38 |

||

|

125mm<l公称≤200mm |

28 |

32 |

36 |

40 |

44 |

|||

|

c min |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

|||

|

da max |

F型 |

9.2 |

11.2 |

13.7 |

15.7 |

17.7 |

||

|

U型 |

10 |

12.5 |

15.2 |

17.7 |

20.5 |

|||

|

dc max |

17 |

20.8 |

24.7 |

28.6 |

32.8 |

|||

|

ds |

max |

8.00 |

10.00 |

12.00 |

14.00 |

16.00 |

||

|

min |

7.78 |

9.78 |

11.73 |

13.73 |

15.73 |

|||

|

dv |

max |

8.8 |

10.8 |

12.8 |

14.8 |

17.2 |

||

|

dw |

min |

14.9 |

18.7 |

22.5 |

26.4 |

30.6 |

||

|

e |

min |

10.95 |

14.26 |

16.50 |

19.86 |

23.15 |

||

|

k |

max |

8.5 |

9.7 |

12.1 |

12.9 |

15.2 |

||

|

kw |

min |

3.8 |

4.3 |

5.4 |

5.6 |

6.8 |

||

|

lf |

max |

2.1 |

2.1 |

2.1 |

2.1 |

3.2 |

||

|

r1 |

min |

0.4 |

0.4 |

0.6 |

0.6 |

0.6 |

||

|

r2e |

max |

0.5 |

0.6 |

0.7 |

0.9 |

1 |

||

|

r3 |

max |

0.36 |

0.45 |

0.54 |

0.63 |

0.72 |

||

|

min |

0.16 |

0.20 |

0.24 |

0.28 |

0.32 |

|||

|

r4参考 |

5.7 |

5.7 |

5.7 |

5.7 |

8.8 |

|||

|

s |

max |

10.00 |

13.00 |

15.00 |

18.00 |

21.00 |

||

|

min |

9.78 |

12.73 |

14.73 |

17.73 |

20.67 |

|||

|

v |

max |

0.25 |

0.30 |

0.35 |

0.45 |

0.50 |

||

|

min |

0.10 |

0.15 |

0.15 |

0.20 |

0.25 |

|||

|

l |

35~80 |

40~100 |

45~120 |

50~140 |

55~160 |

|||

|

全螺纹长 l |

35 |

40 |

45 |

50 |

55 |

|||

|

螺栓公称范围 |

16,20,25,30,35,40,45,50,55,60,65,70,80,90,100,110,120,130,140,150,160 |

|||||||

|

技术条件和引用标准 |

||||||||

|

材 料 |

钢 |

不锈钢 |

||||||

|

通过技术条件 |

GB/T 16938 |

|||||||

|

螺 纹 |

公 差 |

6 g |

||||||

|

标 准 |

GB/T 196、GB/T 197 |

|||||||

|

机械性能 |

等 级 |

8.8、9.8、10.9、12.9 |

A2-70 |

|||||

|

标 准 |

GB/T 3098.1 |

GB/T 3098.6 |

||||||

|

公 差 |

产品等级 |

A |

||||||

|

标 准 |

GB/T 3103.1 |

|||||||

|

表面处理 |

氧化(热的或化学的); 电镀层技术要求按GB/T 5267.1 |

简单处理 |

||||||

|

如需要其他的电镀层或表面处理,应由供需双方协议 |

||||||||

|

表面缺陷 |

GB/T 5779.3 |

|||||||

|

验收及包装 |

GB/T 90.1、GB/T 90.2 |

|||||||

|

质量 kg |

|||||||

|

螺纹规格 |

M8×1 |

M10×1 |

M10×1.25 |

M12×1.25 |

M12×1.5 |

M14×1.5 |

M16×1.5 |

|

公称长度/mm |

每1000件钢制品的质量 ≈ |

||||||

|

35 |

16.64 |

|

|

|

|

|

|

|

40 |

18.51 |

30.82 |

30.20 |

|

|

|

|

|

45 |

20.37 |

33.77 |

33.15 |

50.29 |

49.40 |

|

|

|

50 |

22.24 |

36.72 |

36.09 |

54.53 |

53.64 |

76.05 |

|

|

55 |

24.10 |

39.67 |

39.04 |

58.77 |

57.88 |

81.86 |

114.1 |

|

60 |

25.97 |

42.62 |

41.99 |

63.01 |

62.12 |

87.67 |

121.8 |

|

65 |

27.84 |

45.57 |

44.94 |

67.25 |

66.37 |

93.48 |

129.4 |

|

70 |

29.70 |

48.52 |

47.89 |

71.49 |

70.61 |

99.29 |

137.0 |

|

80 |

33.43 |

54.41 |

53.79 |

79.98 |

79.09 |

110.9 |

152.3 |

|

90 |

|

60.31 |

59.68 |

88.46 |

87.57 |

122.5 |

167.5 |

|

100 |

|

66.21 |

65.58 |

96.94 |

96.06 |

134.2 |

182.8 |

|

110 |

|

|

|

105.4 |

104.5 |

145.8 |

198.0 |

|

120 |

|

|

|

113.9 |

113.0 |

157.4 |

213.3 |

|

130 |

|

|

|

|

|

168.3 |

227.7 |

|

140 |

|

|

|

|

|

179.9 |

242.9 |

|

150 |

|

|

|

|

|

|

258.2 |

|

160 |

|

|

|

|

|

|

273.4 |

|

螺纹规格 |

M8×1 |

M10×1 |

M10×1.25 |

M12×1.25 |

M12×1.5 |

M14×1.5 |

M16×1.5 |

|

公称长度/mm |

每1000件钢制品的质量 ≈ |

||||||

|

35 |

16.70 |

|

|

|

|

|

|

|

40 |

18.34 |

31.03 |

30.46 |

|

|

|

|

|

45 |

19.97 |

33.69 |

33.03 |

50.78 |

50.02 |

|

|

|

50 |

21.61 |

36.35 |

35.60 |

54.59 |

53.72 |

77.07 |

|

|

55 |

23.25 |

39.01 |

38.16 |

58.40 |

57.42 |

82.24 |

115.5 |

|

60 |

24.89 |

41.67 |

40.73 |

62.21 |

61.12 |

87.41 |

122.3 |

|

65 |

26.53 |

44.33 |

43.30 |

66.03 |

64.81 |

92.59 |

129.2 |

|

70 |

28.17 |

46.99 |

45.87 |

69.84 |

68.51 |

97.76 |

136.1 |

|

80 |

31.44 |

52.31 |

51.00 |

77.46 |

75.91 |

108.1 |

149.9 |

|

90 |

|

57.63 |

56.13 |

85.09 |

83.30 |

118.4 |

163.7 |

|

100 |

|

62.95 |

61.27 |

92.71 |

90.70 |

128.8 |

177.5 |

|

110 |

|

|

|

100.3 |

98.09 |

139.1 |

191.3 |

|

120 |

|

|

|

108.0 |

105.5 |

149.5 |

205.0 |

|

130 |

|

|

|

|

|

159.8 |

218.8 |

|

140 |

|

|

|

|

|

170.2 |

232.6 |

|

150 |

|

|

|

|

|

|

246.4 |

|

160 |

|

|

|

|

|

|

260.2 |