轴套与轴瓦

轴套

铜合金轴套(GB/T18324-2001)

|

铜合金轴套(GB/T 18324—2001) |

|---|

|

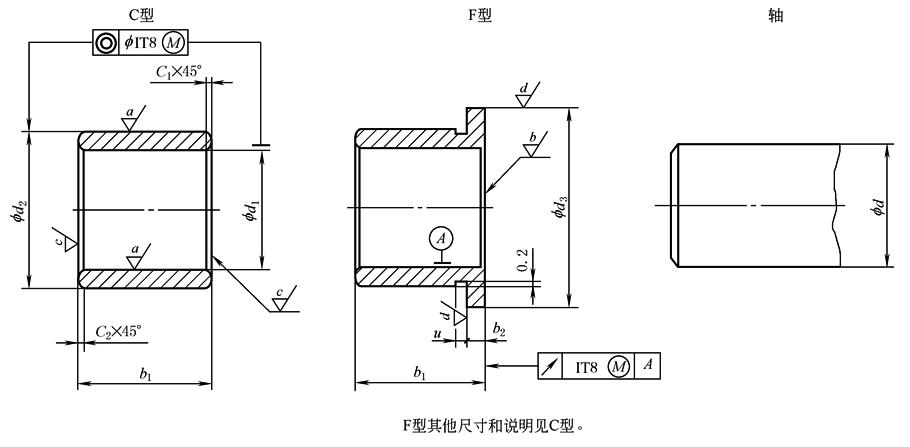

材料 铸造铜合金应符合JB/T 7921—1995(铸造铜合金)的要求。 锻造铜合金应符合JB/T 7922—1995(锻造铜合金)的要求。 (以上两标准分别为原标准G 10448和G 10449) 标记示例: C型轴套内径d1=20mm,外径d2=24mm,宽度b1=20mm,协商而定的外圆倒角C2为15°(Y),材料为符合GB/T18324的CuSn8P,标记为:轴套GB/T18324—C20×24×20Y—CuSn8P |

|

表1 C型铜合金轴套 |

|||||||||||||||||

|

内径 d1 |

外径d2 |

宽度b1 |

倒角 |

内径 d1 |

外径d2 |

宽度b1 |

倒角 |

||||||||||

|

45° C1,C2 max |

15° C2 max |

45° C1,C2 max |

15° C2 max |

||||||||||||||

|

6 |

8 |

10 |

12 |

6 |

10 |

— |

0.3 |

1 |

48 |

53 |

56 |

58 |

40 |

50 |

60 |

0.8 |

3 |

|

8 |

10 |

12 |

14 |

6 |

10 |

— |

0.3 |

1 |

50 |

55 |

58 |

60 |

40 |

50 |

60 |

0.8 |

3 |

|

10 |

12 |

14 |

16 |

6 |

10 |

— |

0.3 |

1 |

55 |

60 |

63 |

65 |

40 |

50 |

70 |

0.8 |

3 |

|

12 |

14 |

16 |

18 |

10 |

15 |

20 |

0.5 |

2 |

60 |

65 |

70 |

75 |

40 |

60 |

80 |

0.8 |

3 |

|

14 |

16 |

18 |

20 |

10 |

15 |

20 |

0.5 |

2 |

65 |

70 |

75 |

80 |

50 |

60 |

80 |

1 |

4 |

|

15 |

17 |

19 |

21 |

10 |

15 |

20 |

0.5 |

2 |

70 |

75 |

80 |

85 |

50 |

70 |

90 |

1 |

4 |

|

16 |

18 |

20 |

22 |

12 |

15 |

20 |

0.5 |

2 |

75 |

80 |

85 |

90 |

50 |

70 |

90 |

1 |

4 |

|

18 |

20 |

22 |

24 |

12 |

20 |

30 |

0.5 |

2 |

80 |

85 |

90 |

95 |

60 |

80 |

100 |

1 |

4 |

|

20 |

23 |

24 |

26 |

15 |

20 |

30 |

0.5 |

2 |

85 |

90 |

95 |

100 |

60 |

80 |

100 |

1 |

4 |

|

22 |

25 |

26 |

28 |

15 |

20 |

30 |

0.5 |

2 |

90 |

100 |

105 |

110 |

60 |

80 |

120 |

1 |

4 |

|

(24) |

27 |

28 |

30 |

15 |

20 |

30 |

0.5 |

2 |

95 |

105 |

110 |

115 |

60 |

100 |

120 |

1 |

4 |

|

25 |

28 |

30 |

32 |

20 |

30 |

40 |

0.5 |

2 |

100 |

110 |

115 |

120 |

80 |

100 |

120 |

1 |

4 |

|

(27) |

30 |

32 |

34 |

20 |

30 |

40 |

0.5 |

2 |

105 |

115 |

120 |

125 |

80 |

100 |

120 |

1 |

4 |

|

28 |

32 |

34 |

36 |

20 |

30 |

40 |

0.5 |

2 |

110 |

120 |

125 |

130 |

80 |

100 |

120 |

1 |

4 |

|

30 |

34 |

36 |

38 |

20 |

30 |

40 |

0.5 |

2 |

120 |

130 |

135 |

140 |

100 |

120 |

150 |

1 |

4 |

|

32 |

36 |

38 |

40 |

20 |

30 |

40 |

0.8 |

3 |

130 |

140 |

145 |

150 |

100 |

120 |

150 |

2 |

5 |

|

(33) |

37 |

40 |

42 |

20 |

30 |

40 |

0.8 |

3 |

140 |

150 |

155 |

160 |

100 |

150 |

180 |

2 |

5 |

|

35 |

39 |

41 |

45 |

30 |

40 |

50 |

0.8 |

3 |

150 |

160 |

165 |

170 |

120 |

150 |

180 |

2 |

5 |

|

(36) |

40 |

42 |

46 |

30 |

40 |

50 |

0.8 |

3 |

160 |

170 |

180 |

185 |

120 |

150 |

180 |

2 |

5 |

|

38 |

42 |

45 |

48 |

30 |

40 |

50 |

0.8 |

3 |

170 |

180 |

190 |

195 |

120 |

180 |

200 |

2 |

5 |

|

40 |

44 |

48 |

50 |

30 |

40 |

60 |

0.8 |

3 |

180 |

190 |

200 |

210 |

150 |

180 |

250 |

2 |

5 |

|

42 |

46 |

50 |

52 |

30 |

40 |

60 |

0.8 |

3 |

190 |

200 |

210 |

220 |

150 |

180 |

250 |

2 |

5 |

|

45 |

50 |

53 |

55 |

30 |

40 |

60 |

0.8 |

3 |

200 |

210 |

220 |

230 |

180 |

200 |

250 |

2 |

5 |

|

注:1.括号内的值仅作特殊用途,应尽可能避免使用。 2.外圆倒角C2为45°的,不要求进行专门详细的标记。外圆倒角C2为15°的,规定在标记中另加Y。 |

|||||||||||||||||

|

表2 F型铜合金轴套 |

||||||||||||

|

内径 d1 |

外径 d2 |

翻边 外径 d3 |

翻边 宽度 b2 |

外径 d2 |

翻边 外径 d3 |

翻边 宽度 b2 |

宽度b1 |

倒角 |

退刀槽宽度 u |

|||

|

45° C1,C2 max |

15° C2 max |

|||||||||||

|

第一系列 |

第二系列 |

|||||||||||

|

6 |

8 |

10 |

1 |

12 |

14 |

3 |

— |

10 |

— |

0.3 |

1 |

1 |

|

8 |

10 |

12 |

1 |

14 |

18 |

3 |

— |

10 |

— |

0.3 |

1 |

1 |

|

10 |

12 |

14 |

1 |

16 |

20 |

3 |

— |

10 |

— |

0.3 |

1 |

1 |

|

12 |

14 |

16 |

1 |

18 |

22 |

3 |

10 |

15 |

20 |

0.5 |

2 |

1 |

|

14 |

16 |

18 |

1 |

20 |

25 |

3 |

10 |

15 |

20 |

0.5 |

2 |

1 |

|

15 |

17 |

19 |

1 |

21 |

27 |

3 |

10 |

15 |

20 |

0.5 |

2 |

1 |

|

16 |

18 |

20 |

1 |

22 |

28 |

3 |

12 |

15 |

20 |

0.5 |

2 |

1.5 |

|

18 |

20 |

22 |

1 |

24 |

30 |

3 |

12 |

20 |

30 |

0.5 |

2 |

1.5 |

|

20 |

23 |

26 |

1.5 |

26 |

32 |

3 |

15 |

20 |

30 |

0.5 |

2 |

1.5 |

|

22 |

25 |

28 |

1.5 |

28 |

34 |

3 |

15 |

20 |

30 |

0.5 |

2 |

1.5 |

|

(24) |

27 |

30 |

1.5 |

30 |

36 |

3 |

15 |

20 |

30 |

0.5 |

2 |

1.5 |

|

25 |

28 |

31 |

1.5 |

32 |

38 |

4 |

20 |

30 |

40 |

0.5 |

2 |

1.5 |

|

(27) |

30 |

33 |

1.5 |

34 |

40 |

4 |

20 |

30 |

40 |

0.5 |

2 |

1.5 |

|

28 |

32 |

36 |

2 |

36 |

42 |

4 |

20 |

30 |

40 |

0.5 |

2 |

1.5 |

|

30 |

34 |

38 |

2 |

38 |

44 |

4 |

20 |

30 |

40 |

0.5 |

2 |

2 |

|

32 |

36 |

40 |

2 |

40 |

46 |

4 |

20 |

30 |

40 |

0.8 |

3 |

2 |

|

(33) |

37 |

41 |

2 |

42 |

48 |

5 |

20 |

30 |

40 |

0.8 |

3 |

2 |

|

35 |

39 |

43 |

2 |

45 |

50 |

5 |

30 |

40 |

50 |

0.8 |

3 |

2 |

|

(36) |

40 |

44 |

2 |

46 |

52 |

5 |

30 |

40 |

50 |

0.8 |

3 |

2 |

|

38 |

42 |

46 |

2 |

48 |

54 |

5 |

30 |

40 |

50 |

0.8 |

3 |

2 |

|

40 |

44 |

48 |

2 |

50 |

58 |

5 |

30 |

40 |

60 |

0.8 |

3 |

2 |

|

42 |

46 |

50 |

2 |

52 |

60 |

5 |

30 |

40 |

60 |

0.8 |

3 |

2 |

|

45 |

50 |

55 |

2.5 |

55 |

63 |

5 |

30 |

40 |

60 |

0.8 |

3 |

2 |

|

48 |

53 |

58 |

2.5 |

58 |

66 |

5 |

40 |

50 |

60 |

0.8 |

3 |

2 |

|

50 |

55 |

60 |

2.5 |

60 |

68 |

5 |

40 |

50 |

60 |

0.8 |

3 |

2 |

|

55 |

60 |

65 |

2.5 |

65 |

73 |

5 |

40 |

50 |

70 |

0.8 |

3 |

2 |

|

60 |

65 |

70 |

2.5 |

75 |

83 |

7.5 |

40 |

60 |

80 |

0.8 |

3 |

2 |

|

65 |

70 |

75 |

2.5 |

80 |

88 |

7.5 |

50 |

60 |

80 |

1 |

4 |

2 |

|

70 |

75 |

80 |

2.5 |

85 |

95 |

7.5 |

50 |

70 |

90 |

1 |

4 |

2 |

|

75 |

80 |

85 |

2.5 |

90 |

100 |

7.5 |

50 |

70 |

90 |

1 |

4 |

3 |

|

80 |

85 |

90 |

2.5 |

95 |

105 |

7.5 |

60 |

80 |

100 |

1 |

4 |

3 |

|

85 |

90 |

95 |

2.5 |

100 |

110 |

7.5 |

60 |

80 |

100 |

1 |

4 |

3 |

|

90 |

100 |

110 |

5 |

110 |

120 |

10 |

60 |

80 |

120 |

1 |

4 |

3 |

|

95 |

105 |

115 |

5 |

115 |

125 |

10 |

60 |

100 |

120 |

1 |

4 |

3 |

|

100 |

110 |

120 |

5 |

120 |

130 |

10 |

80 |

100 |

120 |

1 |

4 |

3 |

|

105 |

115 |

125 |

5 |

125 |

135 |

10 |

80 |

100 |

120 |

1 |

4 |

3 |

|

110 |

120 |

130 |

5 |

130 |

140 |

10 |

80 |

100 |

120 |

1 |

4 |

3 |

|

120 |

130 |

140 |

5 |

140 |

150 |

10 |

100 |

120 |

150 |

1 |

4 |

3 |

|

130 |

140 |

150 |

5 |

150 |

160 |

10 |

100 |

120 |

150 |

2 |

5 |

4 |

|

140 |

150 |

160 |

5 |

160 |

170 |

10 |

100 |

150 |

180 |

2 |

5 |

4 |

|

150 |

160 |

170 |

5 |

170 |

180 |

10 |

120 |

150 |

180 |

2 |

5 |

4 |

|

160 |

170 |

180 |

5 |

185 |

200 |

12.5 |

120 |

150 |

180 |

2 |

5 |

4 |

|

170 |

180 |

190 |

5 |

195 |

210 |

12.5 |

120 |

180 |

200 |

2 |

5 |

4 |

|

180 |

190 |

200 |

5 |

210 |

220 |

15 |

150 |

180 |

250 |

2 |

5 |

4 |

|

190 |

200 |

210 |

5 |

220 |

230 |

15 |

150 |

180 |

250 |

2 |

5 |

4 |

|

200 |

210 |

220 |

5 |

230 |

240 |

15 |

180 |

200 |

250 |

2 |

5 |

4 |

|

注:1.括号内的值仅作特殊用途,应尽可能避免使用。 2.F型图见表1的表头图。 3.F型翻边轴套是否带退刀槽(尺寸u)应根据供需双方协议而定。 |

||||||||||||

公差与表面粗糙度

|

公差与表面粗糙度 |

|||||||

|---|---|---|---|---|---|---|---|

|

公差 |

内径d1 |

外径d2 |

翻边外径d3 |

宽度b1 |

轴承座孔 |

轴径d |

|

|

E6① |

≤120 |

s6 |

d1 |

h13 |

H7 |

e7或g7② |

|

|

>120 |

r6 |

||||||

|

表面 粗糙度 |

表面粗糙度应根据GB/T131标注(见表铜合金轴套表头图),如:

|

||||||

|

① 冲压后,d1通常可达到公差位置H,公差等级大约为IT8。 ② 根据使用情况来推荐所用的公差。如果轴套与公差位置h的精密磨削轴制成品相配合,内径d1的公差应为D6,它装配后的概率公差为F8;如果轴套内孔是装配后加工,内径d1的尺寸公差应由供需双方协议而定。 注:用尺寸d2来确定关于同轴度公差的IT值。用尺寸d3来确定关于轴肩端面跳动的IT值。 |

|||||||

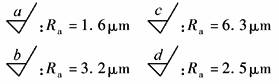

铸铁轴套

|

铸铁轴套 mm |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||

|

d(H8) |

D(S7) |

d1 |

l |

l1 |

h |

r |

r1 |

C |

C1 |

|

10 |

15 |

5 |

20 |

3 |

0.5 |

1 |

7 |

0.5 |

1 |

|

11 |

16 |

||||||||

|

12 |

18 |

1.0 |

2 |

||||||

|

14 |

20 |

24 |

|||||||

|

16 |

22 |

||||||||

|

18 |

25 |

30 |

|||||||

|

20 |

28 |

1.5 |

3 |

||||||

|

22 |

30 |

34 |

|||||||

|

25 |

32 |

38 |

4 |

||||||

|

28 |

36 |

42 |

|||||||

|

30 |

38 |

48 |

1 |

1.5 |

|||||

|

32 |

40 |

||||||||

|

36 |

45 |

55 |

5 |

||||||

|

40 |

50 |

60 |

|||||||

|

45 |

55 |

70 |

|||||||

|

50 |

60 |

75 |

|||||||

|

55 |

65 |

8 |

80 |

6 |

2.5 |

5 |

9 |

||

|

60 |

70 |

90 |

|||||||

|

70 |

85 |

100 |

|||||||

|

80 |

95 |

||||||||

|

90 |

105 |

120 |

1.5 |

2 |

|||||

|

100 |

115 |

8 |

|||||||

|

110 |

125 |

140 |

|||||||

|

125 |

140 |

150 |

|||||||

|

130 |

150 |

||||||||

|

140 |

160 |

170 |

|||||||

|

150 |

170 |

||||||||

|

160 |

180 |

190 |

|||||||

|

180 |

200 |

200 |

|||||||

|

注:1.直径 D 允许采用 n7、m7、k7、j7 配合。直径 d 允许采用 H7 配合。 2.轴套和轴承座孔用螺钉固定,尺寸见表轻载轴套固定方式。 3.压合后轴套的直径 d 可能缩小,因此装配后必须检查,必要时应进行精加工。 |

|||||||||

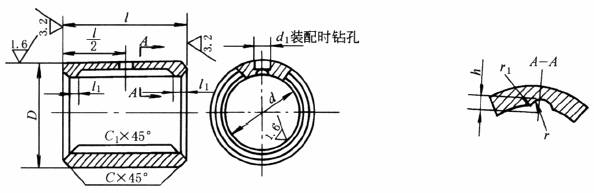

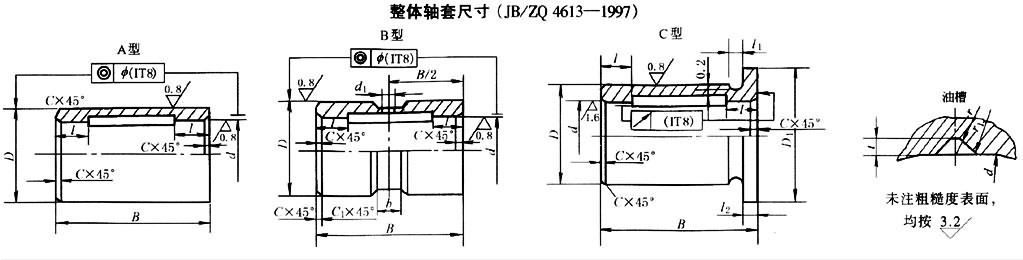

整体轴套尺寸(JB/ZQ4613-2006)

|

整体轴套尺寸 (JB/ZQ 4613—2006) /mm |

||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

|

d |

D |

D1 |

L |

d1 |

l1 |

l2 (h12) |

t

|

b |

r |

r1 |

C |

C1 |

重量(每1000件)/kg |

|||||||||

|

1 |

2 |

3 |

4 |

A 型 |

B 型 |

C 型 |

||||||||||||||||

|

1 |

2 |

3 |

4 |

1 |

2 |

3 |

||||||||||||||||

|

20 |

26 |

32 |

15 |

20 |

30 |

30 |

6 |

1.5 |

3 |

1.2 |

12 |

2.5 |

6 |

0.5 |

1 |

28.6 |

38.2 |

57.2 |

57.2 |

35.8 |

45.4 |

64.4 |

|

22 |

28 |

34 |

31.1 |

41.5 |

62.2 |

62.2 |

38.8 |

49.2 |

69.9 |

|||||||||||||

|

25 |

32 |

38 |

20 |

30 |

40 |

40 |

4 |

1.6 |

3 |

9 |

55.2 |

82.7 |

110.3 |

110.3 |

66.8 |

94.3 |

121.9 |

|||||

|

28 |

36 |

42 |

50 |

70.8 |

106.2 |

141.5 |

176.8 |

83.7 |

119.1 |

154.4 |

||||||||||||

|

30 |

38 |

44 |

2 |

75.2 |

112.8 |

150.4 |

188.0 |

88.8 |

126.4 |

164.0 |

||||||||||||

|

32 |

40 |

46 |

55 |

0.8 |

79.6 |

119.4 |

159.2 |

218.9 |

93.8 |

133.6 |

173.4 |

|||||||||||

|

35 |

45 |

50 |

30 |

40 |

50 |

8 |

5 |

2 |

16 |

4 |

12 |

1.5 |

165.9 |

221.2 |

276.5 |

304.1 |

182.3 |

237.6 |

292.9 |

|||

|

(36) |

46 |

52 |

60 |

170.0 |

226.7 |

283.4 |

311.7 |

190.3 |

247.0 |

303.7 |

||||||||||||

|

40 |

50 |

58 |

60 |

186.6 |

248.8 |

373.2 |

373.2 |

216.4 |

278.6 |

403.0 |

||||||||||||

|

45 |

55 |

63 |

70 |

207.3 |

276.5 |

414.7 |

483.8 |

239.9 |

309.1 |

447.3 |

||||||||||||

|

50 |

60 |

68 |

40 |

50 |

75 |

304 |

380 |

456 |

570 |

339 |

415 |

491 |

||||||||||

|

55 |

65 |

73 |

70 |

80 |

332 |

415 |

581 |

664 |

370 |

453 |

619 |

|||||||||||

|

60 |

75 |

83 |

60 |

80 |

7.5 |

2.5 |

5 |

15 |

560 |

840 |

1120 |

1120 |

625 |

905 |

1185 |

|||||||

|

65 |

80 |

88 |

50 |

100 |

1 |

752 |

902 |

1203 |

1504 |

821 |

971 |

1272 |

||||||||||

|

70 |

85 |

95 |

70 |

90 |

10 |

20 |

803 |

1125 |

1446 |

1606 |

896 |

1218 |

1539 |

|||||||||

|

75 |

90 |

100 |

3 |

855 |

1197 |

1540 |

1711 |

953 |

1295 |

1638 |

||||||||||||

|

80 |

95 |

105 |

60 |

80 |

100 |

1089 |

1451 |

1814 |

1814 |

1192 |

1554 |

1917 |

||||||||||

|

90 |

110 |

120 |

120 |

120 |

10 |

3.2 |

7 |

21 |

1659 |

2212 |

3318 |

3318 |

1817 |

2370 |

3476 |

|||||||

|

100 |

120 |

130 |

80 |

100 |

2433 |

3041 |

3649 |

3649 |

2605 |

3213 |

3820 |

|||||||||||

|

110 |

130 |

140 |

140 |

2654 |

3317 |

3981 |

4644 |

2840 |

3503 |

4167 |

||||||||||||

|

120 |

140 |

150 |

100 |

120 |

150 |

150 |

12 |

25 |

2 |

3594 |

4313 |

5391 |

5359 |

3794 |

4513 |

5591 |

||||||

|

130 |

150 |

160 |

170 |

4 |

2 |

3871 |

4645 |

5806 |

6580 |

4085 |

4859 |

6020 |

||||||||||

|

140 |

160 |

170 |

150 |

180 |

4147 |

6220 |

7464 |

7049 |

4375 |

6448 |

7692 |

|||||||||||

|

150 |

170 |

180 |

120 |

— |

— |

— |

— |

5308 |

6635 |

7962 |

— |

5549 |

6876 |

8203 |

||||||||

|

160 |

185 |

200 |

12.5 |

1 |

9 |

27 |

7153 |

8942 |

10730 |

— |

7651 |

9440 |

11228 |

|||||||||

|

170 |

195 |

210 |

180 |

200 |

7568 |

11352 |

12614 |

— |

8092 |

11876 |

13138 |

|||||||||||

|

180 |

210 |

220 |

150 |

180 |

250 |

— |

— |

4 |

15 |

4 |

— |

2 |

— |

12130 |

14556 |

20216 |

— |

12575 |

15001 |

20661 |

||

|

190 |

220 |

230 |

12751 |

15302 |

21253 |

— |

13217 |

15768 |

21719 |

|||||||||||||

|

200 |

230 |

240 |

180 |

200 |

16049 |

17832 |

22290 |

— |

16536 |

18319 |

22777 |

|||||||||||

|

注:1.当 B=15~30mm 时 l=3mm,当 B>30~60mm 时 l=4mm,当 B>60~100mm 时 l=6mm,当 B>100mm 时 l=10mm。 2.轴套的材料:ZCuAl10Fe3。 3.B 型轴套适用于 JB/T 2560《整体有衬正滑动轴承座型式与尺寸》规定的轴承座。 4.油槽应符合 JB/ZQ 4615。 5.括号内尺寸尽量不选用。 |

||||||||||||||||||||||

整体轴套的公差配合(JB/ZQ4613-2006)

|

整体轴套的公差配合 (JB/ZQ 4613—2006) |

|||||||

|---|---|---|---|---|---|---|---|

|

尺 寸 |

装 配 形 式 |

||||||

|

压 入 |

粘 合 |

||||||

|

d |

装入前 |

G7 |

E9 |

D10 |

H7 |

H8 |

E9 |

|

装入后 |

H7 |

H8 |

E9 |

|

|

|

|

|

相配轴的公差 |

g6,f7,e9 |

h9,h11 |

g6,f7,e9 |

h9,h11 |

|||

|

D |

≤120mm |

s 6 |

|

||||

|

>120mm |

r 6 |

g6 |

|||||

|

轴承座孔的公差 |

H7 |

||||||

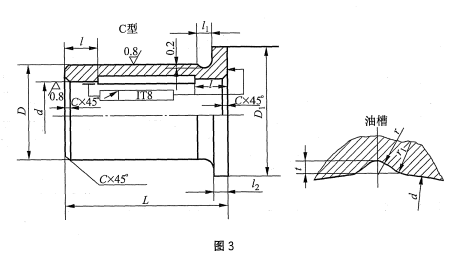

整体轴套尺寸(摘自JB/ZQ 4613-1997)

注:1. 当B=15~30mm时l=3mm,当B>30~60mm时l=4mm,当B>60~100mm时l=6mm,当B>100mm时l=10mm。

2. 轴套的材料:ZCuAl10Fe3。

3. B型轴套适用于JB/T 2560-1991《整体有衬正滑动轴承座型式与尺寸》规定的轴承座。

4. 油槽应符合JB/ZQ 4615-1997。

5. 括号内尺寸尽量不选用。

6. 本表的单位是mm。

| d | D | D1 | B | d1 | l1 |

l2 (h12) |

t (+0.2 ,0) |

b | r | r1 | C | C1 | 重量(每1000件)/kg | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | A型 | B型 | C型 | ||||||||||||||||

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | ||||||||||||||||

| 20 | 26 | 32 | 15 | 20 | 30 | 30 | 6 | 1.5 | 3 | 1.2 | 12 | 2.5 | 6 | 0.5 | 1 | 28.6 | 38.2 | 57.2 | 57.2 | 35.8 | 45.4 | 64.4 |

| 22 | 28 | 34 | 15 | 20 | 30 | 30 | 6 | 1.5 | 3 | 1.2 | 12 | 2.5 | 6 | 0.5 | 1 | 31.1 | 41.5 | 62.2 | 62.2 | 38.8 | 49.2 | 69.9 |

| 25 | 32 | 38 | 20 | 30 | 40 | 40 | 6 | 1.5 | 4 | 1.6 | 12 | 3 | 9 | 0.5 | 1 | 55.2 | 82.7 | 110.3 | 110.3 | 66.8 | 94.3 | 121.9 |

| 28 | 36 | 42 | 20 | 30 | 40 | 50 | 6 | 1.5 | 4 | 1.6 | 12 | 3 | 9 | 0.5 | 1 | 70.8 | 106.2 | 141.5 | 176.8 | 83.7 | 119.1 | 154.4 |

| 30 | 38 | 44 | 20 | 30 | 40 | 50 | 6 | 2 | 4 | 1.6 | 12 | 3 | 9 | 0.5 | 1 | 75.2 | 112.8 | 150.4 | 188 | 88.8 | 126.4 | 164 |

| 32 | 40 | 46 | 20 | 30 | 40 | 55 | 6 | 2 | 4 | 1.6 | 12 | 3 | 9 | 0.8 | 1 | 79.6 | 119.4 | 159.2 | 218.9 | 93.8 | 133.6 | 173.4 |

| 35 | 45 | 50 | 30 | 40 | 50 | 55 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 165.9 | 221.2 | 276.5 | 304.1 | 182.3 | 237.6 | 292.9 |

| (36) | 46 | 52 | 30 | 40 | 50 | 60 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 170 | 226.7 | 283.4 | 311.7 | 190.3 | 247 | 303.7 |

| 40 | 50 | 58 | 30 | 40 | 60 | 60 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 186.6 | 248.8 | 373.2 | 373.2 | 216.4 | 278.6 | 403 |

| 45 | 55 | 63 | 30 | 40 | 60 | 70 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 207.3 | 276.5 | 414.7 | 483.8 | 239.9 | 309.1 | 447.3 |

| 50 | 60 | 68 | 40 | 50 | 60 | 75 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 304 | 380 | 456 | 570 | 339 | 415 | 491 |

| 55 | 65 | 73 | 40 | 50 | 70 | 80 | 8 | 2 | 5 | 2 | 16 | 4 | 12 | 0.8 | 1.5 | 332 | 415 | 581 | 664 | 370 | 453 | 619 |

| 60 | 75 | 83 | 40 | 60 | 80 | 80 | 8 | 2 | 7.5 | 2.5 | 16 | 5 | 15 | 0.8 | 1.5 | 560 | 840 | 1120 | 1120 | 625 | 905 | 1185 |

| 65 | 80 | 88 | 50 | 60 | 80 | 100 | 8 | 2 | 7.5 | 2.5 | 16 | 5 | 15 | 1 | 1.5 | 752 | 902 | 1203 | 1504 | 821 | 971 | 1272 |

| 70 | 85 | 95 | 50 | 70 | 90 | 100 | 10 | 2 | 7.5 | 2.5 | 20 | 5 | 15 | 1 | 1.5 | 803 | 1125 | 1446 | 1606 | 896 | 1218 | 1539 |

| 75 | 90 | 100 | 50 | 70 | 90 | 100 | 10 | 3 | 7.5 | 2.5 | 20 | 5 | 15 | 1 | 1.5 | 855 | 1197 | 1540 | 1711 | 953 | 1295 | 1638 |

| 80 | 95 | 105 | 60 | 80 | 100 | 100 | 10 | 3 | 7.5 | 2.5 | 20 | 5 | 15 | 1 | 1.5 | 1089 | 1451 | 1814 | 1814 | 1192 | 1554 | 1917 |

| 90 | 110 | 120 | 60 | 80 | 120 | 120 | 10 | 3 | 10 | 3.2 | 20 | 7 | 21 | 1 | 1.5 | 1659 | 2212 | 3318 | 3318 | 1817 | 2370 | 3476 |

| 100 | 120 | 130 | 80 | 100 | 120 | 120 | 10 | 3 | 10 | 3.2 | 20 | 7 | 21 | 1 | 1.5 | 2433 | 3041 | 3649 | 3649 | 2605 | 3213 | 3820 |

| 110 | 130 | 140 | 80 | 100 | 120 | 140 | 10 | 3 | 10 | 3.2 | 20 | 7 | 21 | 1 | 1.5 | 2654 | 3317 | 3981 | 4644 | 2840 | 3503 | 4167 |

| 120 | 140 | 150 | 100 | 120 | 150 | 150 | 12 | 3 | 10 | 3.2 | 25 | 7 | 21 | 1 | 2 | 3594 | 4313 | 5391 | 5359 | 3794 | 4513 | 5591 |

| 130 | 150 | 160 | 100 | 120 | 150 | 170 | 12 | 4 | 10 | 3.2 | 25 | 7 | 21 | 2 | 2 | 3871 | 4645 | 5806 | 6580 | 4085 | 4859 | 6020 |

| 140 | 160 | 170 | 100 | 150 | 180 | 170 | 12 | 4 | 10 | 3.2 | 25 | 7 | 21 | 2 | 2 | 4147 | 6220 | 7464 | 7049 | 4375 | 6448 | 7692 |

| 150 | 170 | 180 | 120 | 150 | 180 | — | — | 4 | 10 | 3.2 | — | 7 | 21 | 2 | — | 5308 | 6635 | 7962 | — | 5549 | 6876 | 8203 |

| 160 | 185 | 200 | 120 | 150 | 180 | — | — | 4 | 12.5 | 1 | — | 9 | 27 | 2 | — | 7153 | 8942 | 10730 | — | 7651 | 9440 | 11228 |

| 170 | 195 | 210 | 120 | 180 | 200 | — | — | 4 | 12.5 | 1 | — | 9 | 27 | 2 | — | 7568 | 11352 | 12614 | — | 8092 | 11876 | 13138 |

| 180 | 210 | 220 | 150 | 180 | 250 | — | — | 4 | 15 | 4 | — | 9 | 27 | 2 | — | 12130 | 14556 | 20216 | — | 12575 | 15001 | 20661 |

| 190 | 220 | 230 | 150 | 180 | 250 | — | — | 4 | 15 | 4 | — | 9 | 27 | 2 | — | 12751 | 15302 | 21253 | — | 13217 | 15768 | 21719 |

| 200 | 230 | 240 | 180 | 200 | 250 | — | — | 4 | 15 | 4 | — | 9 | 27 | 2 | — | 16049 | 17832 | 22290 | — | 16536 | 18319 | 22777 |

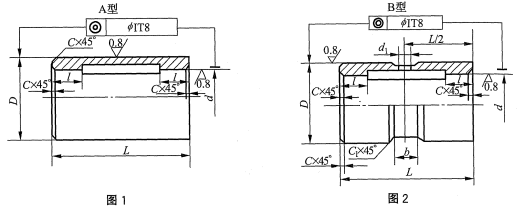

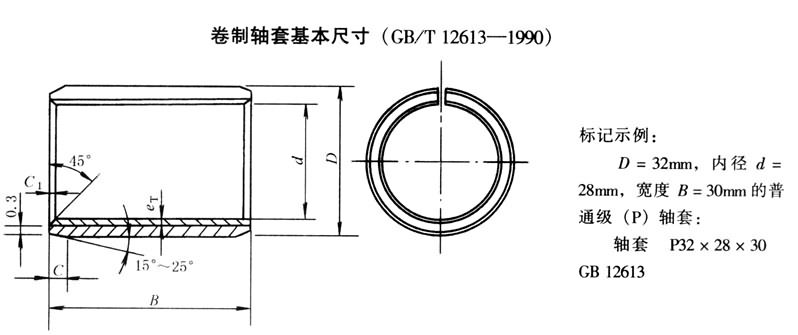

卷制轴套基本尺寸(摘自GB/T 12613-1990)

注:1. 括号内的数值尽量不采用。

2. 本表的单位是mm。

| 外径D | 壁厚eT | C | C1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.75 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | |||

| 内径d | ||||||||||

| 6 | 4.5 | 4 | - | - | - | - | - | - | 棱角、倒角 | 棱角、倒角 |

| 7 | 5.5 | 5 | - | - | - | - | - | - | 棱角、倒角 | 棱角、倒角 |

| 8 | 6.5 | 6 | - | - | - | - | - | - | 棱角、倒角 | 棱角、倒角 |

| 9 | 7.5 | 7 | - | - | - | - | - | - | 棱角、倒角 | 棱角、倒角 |

| 10 | 8.5 | 8 | - | - | - | - | - | - | 棱角、倒角 | 棱角、倒角 |

| 11 | 9.5 | 9 | - | - | - | - | - | - | 0.7 | 0.4 |

| 12 | 10.5 | 10 | - | - | - | - | - | - | 0.7 | 0.4 |

| 13 | 11.5 | 11 | - | - | - | - | - | - | 0.7 | 0.4 |

| 14 | 12.5 | 12 | - | - | - | - | - | - | 0.7 | 0.4 |

| 15 | - | 13 | 12 | - | - | - | - | - | 0.7 | 0.4 |

| 16 | - | 14 | 13 | - | - | - | - | - | 0.7 | 0.4 |

| 17 | - | 15 | 14 | - | - | - | - | - | 0.7 | 0.4 |

| 18 | - | 16 | 15 | - | - | - | - | - | 0.7 | 0.4 |

| 19 | - | 17 | 16 | - | - | - | - | - | 0.7 | 0.4 |

| 20 | - | 18 | 17 | - | - | - | - | - | 0.7 | 0.4 |

| 21 | - | 19 | 18 | - | - | - | - | - | 0.7 | 0.4 |

| 22 | - | 20 | 19 | - | - | - | - | - | 0.7 | 0.4 |

| (23) | - | 21 | 20 | - | - | - | - | - | 0.7 | 0.4 |

| 24 | - | 22 | 21 | - | - | - | - | - | 0.7 | 0.4 |

| 25 | - | 23 | 22 | - | - | - | - | - | 0.7 | 0.4 |

| (27) | - | - | 24 | 23 | - | - | - | - | 1.2 | 0.6 |

| 28 | - | - | 25 | 24 | - | - | - | - | 1.2 | 0.6 |

| 30 | - | - | 27 | 26 | - | - | - | - | 1.2 | 0.6 |

| 32 | - | - | 29 | 28 | - | - | - | - | 1.2 | 0.6 |

| 34 | - | - | 31 | 30 | - | - | - | - | 1.2 | 0.6 |

| 36 | - | - | 33 | 32 | - | - | - | - | 1.2 | 0.6 |

| 38 | - | - | 35 | 34 | - | - | - | - | 1.2 | 0.6 |

| (39) | - | - | 36 | 35 | - | - | - | - | 1.2 | 0.6 |

| 40 | - | - | 37 | 36 | - | - | - | - | 1.2 | 0.6 |

| 42 | - | - | 39 | 38 | - | - | - | - | 1.2 | 0.6 |

| (44) | - | - | 41 | 40 | - | - | - | - | 1.2 | 0.6 |

| 45 | - | - | 42 | 41 | 40 | - | - | - | 1.2 | 0.6 |

| 48 | - | - | 45 | 44 | 43 | - | - | - | 1.2 | 0.6 |

| 50 | - | - | 47 | 46 | 45 | - | - | - | 1.2 | 0.6 |

| 53 | - | - | 50 | 49 | 48 | - | - | - | 1.2 | 0.6 |

| (55) | - | - | - | 51 | 50 | 49 | - | - | 1.2 | 0.6 |

| 56 | - | - | - | 52 | 51 | 50 | - | - | 1.2 | 0.6 |

| (57) | - | - | - | 53 | 52 | 51 | - | - | 1.2 | 0.6 |

| 60 | - | - | - | 56 | 55 | 54 | - | - | 1.2 | 0.6 |

| 63 | - | - | - | 59 | 58 | 57 | - | - | 1.2 | 0.6 |

| 65 | - | - | - | 61 | 60 | 59 | - | - | 1.2 | 0.6 |

| 67 | - | - | - | 63 | 62 | 61 | - | - | 1.2 | 0.6 |

| (70) | - | - | - | 66 | 65 | 64 | - | - | 1.2 | 0.6 |

| 71 | - | - | - | 67 | 66 | 65 | - | - | 1.2 | 0.6 |

| 75 | - | - | - | 71 | 70 | 69 | - | - | 1.2 | 0.6 |

| 80 | - | - | - | 76 | 75 | 74 | - | - | 1.2 | 0.6 |

| 85 | - | - | - | - | 80 | 79 | 78 | - | 2 | 1 |

| 90 | - | - | - | - | 85 | 84 | 83 | - | 2 | 1 |

| 95 | - | - | - | - | 90 | 89 | 88 | - | 2 | 1 |

| 100 | - | - | - | - | 95 | 94 | 93 | - | 2 | 1 |

| 105 | - | - | - | - | 100 | 99 | 98 | - | 2 | 1 |

| 110 | - | - | - | - | 105 | 104 | 103 | - | 2 | 1 |

| (115) | - | - | - | - | 110 | 109 | 108 | - | 2 | 1 |

| 120 | - | - | - | - | 115 | 114 | 113 | - | 2 | 1 |

| 125 | - | - | - | - | 120 | 119 | 118 | - | 2 | 1 |

| 130 | - | - | - | - | - | 124 | 123 | 122 | 2 | 1 |

| 140 | - | - | - | - | - | 134 | 133 | 132 | 2 | 1 |

| 150 | - | - | - | - | - | 144 | 143 | 142 | 2 | 1 |

卷制轴套的推荐宽度(摘自GB/T 12613-1990)

注:1. ○──可用;×──不可用。

2. 本表的单位是mm。

| 外径D | 宽度B | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 100 | |

| 6和7 | ○ | ○ | - | - | - | - | - | - | - | - | - | - |

| 8~10 | - | ○ | ○ | - | - | - | - | - | - | - | - | - |

| 11~15 | - | ○ | ○ | ○ | - | - | - | - | - | - | - | - |

| 16~20 | - | - | ○ | ○ | ○ | - | - | - | - | - | - | - |

| 21~25 | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - | - |

| 26~34 | - | - | - | ○ | ○ | ○ | ○ | - | - | - | - | - |

| 36~48 | - | - | - | - | ○ | ○ | ○ | ○ | - | - | - | - |

| 50~57 | - | - | - | - | ○ | × | ○ | × | ○ | - | - | - |

| 60~67 | - | - | - | - | - | ○ | × | ○ | × | ○ | - | - |

| 70~80 | - | - | - | - | - | - | ○ | × | ○ | × | ○ | - |

| 85~150 | - | - | - | - | - | - | - | ○ | × | ○ | × | ○ |

卷制轴套的公差及表面粗糙度(摘自GB/T 12613-1990)

注:1. 轴套在自由状态下的开缝值t为:D≤50mm,t≤1.5mm;D>50~80mm,t≤3mm;D>80~120mm,t≤4.5mm;D>120mm,t≤6mm。

2. ①处为“其他加工部位”。

| 项目名称 | 外径D公差 | 内径d的公差 | 内外径同轴度公差/mm | 壁厚eT的公差 | 宽度B的公差 | 轴承座孔直径公差 | 表面粗糙度Ra/μm | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D/mm | 公差值/mm | eT/mm | 公差值/mm | 外表面 | 内表面 | ① | |||||

| 普通精度(P) | IT7 | H8 | H8 | — | 0.75 | ±0.035 | h13 | H6或H7 | 1.6 | 6.3 | 12.5 |

| 普通精度(P) | IT7 | H8 | H8 | — | 1,1.5,2,2.5 | ±0.050 | h13 | H6或H7 | 1.6 | 6.3 | 12.5 |

| 普通精度(P) | IT7 | H8 | H8 | — | 3,3.5,4 | ±0.065 | h13 | H6或H7 | 1.6 | 6.3 | 12.5 |

| 高级精度(P) | IT7 | ≤50 | ≤0.025 | ≤0.025 | — | — | h13 | H6或H7 | 1.6 | 0.8 | 12.5 |

| 高级精度(P) | IT7 | >50~80 | ≤0.035 | ≤0.030 | — | — | h13 | H6或H7 | 1.6 | 0.8 | 12.5 |

| 高级精度(P) | IT7 | >80~120 | ≤0.050 | ≤0.040 | — | — | h13 | H6或H7 | 1.6 | 0.8 | 12.5 |

| 高级精度(P) | IT7 | >120~150 | ≤0.070 | ≤0.050 | — | — | h13 | H6或H7 | 1.6 | 0.8 | 12.5 |

覆有减震塑料层双金属卷制轴套的公差及表面粗糙度(摘自GB/T 12949-1991)

| 项目名称 | 尺寸公差 | 形位公差 | 表面粗糙度Ra /μm 外表面 | 表面粗糙度Ra /μm 其余加工部位 |

|---|---|---|---|---|

| 外径D | IT7 | 符合GB 12613-1990的规定 | 3.2 | 25 |

| 内径d | H7 | 符合GB 12613-1990的规定 | 3.2 | 25 |

| 宽度B | h13 | 符合GB 12613-1990的规定 | 3.2 | 25 |

| 与外径相配的座孔 | H7 | 符合GB 12613-1990的规定 | 3.2 | 25 |