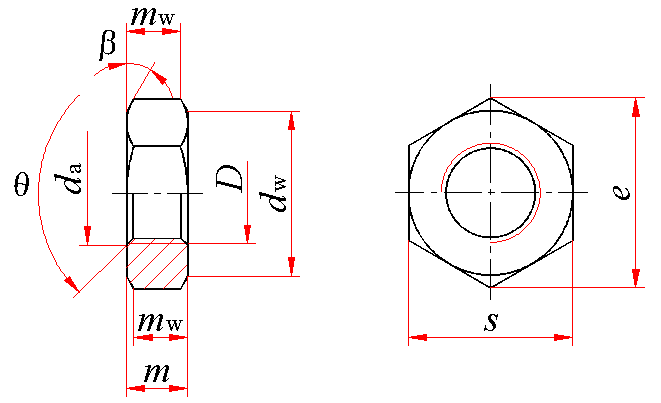

六角薄螺母 细牙(GB/T 6173—2015)

六角薄螺母 细牙(GB/T 6173—2015)

|

六角薄螺母 细牙 (GB/T 6173—2015) mm |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|||||||||

|

β=15°~30°;θ=110°~120° |

|||||||||

|

标记示例: 螺纹规格D=M16×1.5、细牙螺纹、性能等级为05级、不经表面处理、产品等级为A级倒角的六角薄螺母的标记: 螺母 GB/T 6173 M16×1.5 |

|||||||||

|

螺纹规格 D×P |

da |

dw min |

e min |

m |

mw min |

s |

|||

|

max |

min |

max |

min |

公称=max |

min |

||||

|

M8×1 |

8.75 |

8.00 |

11.63 |

14.38 |

4.0 |

3.7 |

2.96 |

13.00 |

12.73 |

|

M10×1 |

10.8 |

10.0 |

14.63 |

17.77 |

5.0 |

4.7 |

3.76 |

16.00 |

15.73 |

|

(M10×1.25) |

10.8 |

10.0 |

14.63 |

17.77 |

5.0 |

4.7 |

3.76 |

16.00 |

15.73 |

|

(M12×1.25) |

13 |

12 |

16.63 |

20.03 |

6.0 |

5.7 |

4.56 |

18.00 |

17.73 |

|

M12×1.5 |

13 |

12 |

16.63 |

20.03 |

6.0 |

5.7 |

4.56 |

18.00 |

17.73 |

|

(M14×1.5) |

15.1 |

14.0 |

19.64 |

23.36 |

7.00 |

6.42 |

5.14 |

21.00 |

20.67 |

|

M16×1.5 |

17.3 |

16.0 |

22.49 |

26.75 |

8.00 |

7.42 |

5.94 |

24.00 |

23.67 |

|

(M18×1.5) |

19.5 |

18.0 |

24.85 |

29.56 |

9.00 |

8.42 |

6.74 |

27.00 |

26.16 |

|

M20×1.5 |

21.6 |

20.0 |

27.7 |

32.95 |

10.0 |

9.1 |

7.28 |

30.00 |

29.16 |

|

(M20×2) |

21.6 |

20.0 |

27.7 |

32.95 |

10.0 |

9.1 |

7.28 |

30.00 |

29.16 |

|

(M22×1.5) |

23.7 |

22.0 |

31.35 |

37.29 |

11.0 |

9.9 |

7.92 |

34 |

33 |

|

M24×2 |

25.9 |

24.0 |

33.25 |

39.55 |

12.0 |

10.9 |

8.72 |

36 |

35 |

|

(M27×2) |

29.1 |

27.0 |

38 |

45.2 |

13.5 |

12.4 |

9.92 |

41 |

40 |

|

M30×2 |

32.4 |

30.0 |

42.75 |

50.85 |

15.0 |

13.9 |

11.12 |

46 |

45 |

|

(M33×2) |

35.6 |

33.0 |

46.55 |

55.37 |

16.5 |

15.4 |

12.32 |

50 |

49 |

|

M36×3 |

38.9 |

36.0 |

51.11 |

60.79 |

18.0 |

16.9 |

13.52 |

55.0 |

53.8 |

|

(M39×3) |

42.1 |

39.0 |

55.86 |

66.44 |

19.5 |

18.2 |

14.56 |

60.0 |

58.8 |

|

M42×3 |

45.4 |

42.0 |

59.95 |

71.3 |

21.0 |

19.7 |

15.76 |

65.0 |

63.1 |

|

(M45×3) |

48.6 |

45.0 |

64.7 |

76.95 |

22.5 |

21.2 |

16.96 |

70.0 |

68.1 |

|

M48×3 |

51.8 |

48.0 |

69.45 |

82.6 |

24.0 |

22.7 |

18.16 |

75.0 |

73.1 |

|

(M52×4) |

56.2 |

52.0 |

74.2 |

88.25 |

26.0 |

24.7 |

19.76 |

80.0 |

78.1 |

|

M56×4 |

60.5 |

56.0 |

78.66 |

93.56 |

28.0 |

26.7 |

21.36 |

85.0 |

82.8 |

|

(M60×4) |

64.8 |

60.0 |

83.41 |

99.21 |

30.0 |

28.7 |

22.96 |

90.0 |

87.8 |

|

M64×4 |

69.1 |

64.0 |

88.16 |

104.86 |

32.0 |

30.4 |

24.32 |

95.0 |

92.8 |

|

技术条件 |

材料 |

螺纹公差 |

机械性能等级 |

公差产品等级 |

表面处理 |

||||

|

钢 |

6H |

D≤M39:04、05 D>M39:按协议 |

D≤16mm:A级 D>16mm:B级 |

不经处理 |

|||||

|

不锈钢 |

D≤M24:A2-035、A4-035 M24<D≤M39:A2-025、A4-025 D>M39:按协议 |

简单处理 |

|||||||

|

有色金属 |

CU2、CU3、AL4 |

简单处理 |

|||||||

|

注:带括号的规格为非优选的螺纹规格。 |

|||||||||

|

质量 kg |

||||||

|

优选的螺纹规格 |

||||||

|

螺纹规格 |

M8×1 |

M10×1 |

M12×1.5 |

M16×1.5 |

M20×1.5 |

M24×2 |

|

每1000件钢制品的质量≈ |

2.67 |

5.03 |

7.39 |

16.74 |

30.07 |

52.30 |

|

螺纹规格 |

M30×2 |

M36×3 |

M42×3 |

M48×3 |

M56×4 |

M64×4 |

|

每1000件钢制品的质量≈ |

112.7 |

197.6 |

315.8 |

492.9 |

722.2 |

997.7 |

|

非优选的螺纹规格 |

||||||

|

螺纹规格 |

M10×1.25 |

M12×1.25 |

M14×1.5 |

M18×1.5 |

M20×2 |

M22×1.5 |

|

每1000件钢制品的质量≈ |

5.12 |

7.26 |

11.15 |

22.46 |

30.75 |

43.21 |

|

螺纹规格 |

M27×2 |

M33×2 |

M39×3 |

M45×3 |

M52×4 |

M60×4 |

|

每1000件钢制品的质量≈ |

78.67 |

145.3 |

255.6 |

397.8 |

609.2 |

857.3 |